Modern architecture is defined by light. From towering skyscrapers wrapped in curtain walls to boutique storefronts featuring seamless glass facades, glazing is the aesthetic and functional skin of contemporary buildings. However, achieving these sleek, transparent looks requires more than just a creative architectural vision. It demands engineering precision.

This is where glazing shop drawings services come into play. They serve as the critical bridge between the architect’s intent and the fabricator’s reality. Without these detailed diagrams, the transition from design to physical construction is fraught with risk.

For construction managers, architects, and fabricators, understanding the necessity of professional glazing shop drawings is not just about paperwork—it is about ensuring the structural integrity, budget adherence, and timely completion of a project.

The Bridge Between Design and Reality

Architectural drawings provide the “big picture.” They show the elevations, the general aesthetic, and how the building should look upon completion. However, they rarely contain the granular manufacturing data required to actually build the glazing systems.

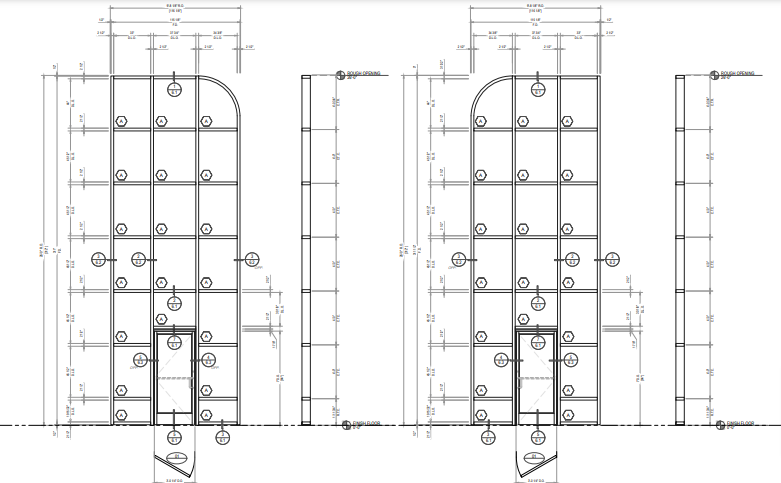

Glazing shop drawings take the architectural intent and translate it into the language of fabrication. They provide the specific dimensions, material specifications, joinery details, and installation methods needed by the glazier.

Translating Intent into Instruction

Think of the architectural drawing as a photograph of a meal, and the shop drawing as the detailed recipe. The shop drawing specifies exact glass thicknesses, the type of sealant required, the thermal breaks in the aluminum framing, and the specific anchors needed to attach the system to the building’s structure.

This translation phase is where “constructability” is determined. A design might look perfect on paper, but physics or material limitations might make it impossible to build without modification. Shop drawings identify these issues early, allowing for adjustments before a single piece of glass is ordered.

The Benefits of Accurate Glazing Shop Drawings

Investing in high-quality shop drawing services offers tangible benefits that extend throughout the lifecycle of a construction project.

Precision and Tolerance Management

Glass is an unforgiving material. Unlike wood, which can be trimmed on-site, or concrete, which can be poured to fit, tempered and insulated glass units are manufactured to exact sizes. You cannot cut tempered glass on a job site; if it doesn’t fit, it is scrap.

Accurate shop drawings calculate tolerances down to the millimeter. They account for the expansion and contraction of aluminum frames, the movement of the building structure, and the necessary clearances for sealants. This precision ensures that when materials arrive on site, they fit the first time.

Clash Detection and Coordination

A building is a complex ecosystem of structural steel, HVAC ducts, electrical conduits, and plumbing. Glazing systems must coexist with these elements without interference.

Shop drawings allow for coordination between trades. Through the drafting process, drafters can identify potential clashes—such as a steel beam interfering with a curtain wall anchor—long before construction begins. Resolving these conflicts digitally is free; resolving them on the construction site is expensive and time-consuming.

Regulatory and Safety Compliance

Glazing systems must withstand significant forces, including wind loads, seismic activity, and the dead load of the glass itself. Shop drawings often undergo review by structural engineers to ensure the system meets local building codes and safety standards.

These drawings document exactly how the system is engineered to perform, providing a paper trail of compliance that is essential for obtaining building permits and passing inspections.

The High Cost of Inaccuracy

The value of shop drawings is perhaps best understood by looking at the consequences of their absence or inaccuracy. Skipping this step or relying on subpar drawings can lead to disastrous outcomes.

Material Wastage and Budget Overruns

Glass fabrication is expensive. Custom insulated units often have lead times of weeks or even months. If a shop drawing is incorrect, the fabricator produces the wrong size or specification.

When that glass arrives on site and doesn’t fit, the cost is threefold: the cost of the wasted material, the cost of re-ordering the new material, and the cost of the labor standing idle while waiting for the replacement. In tight-margin construction projects, these errors can erase profitability entirely.

Schedule Delays

Time is arguably the most valuable resource on a construction site. The building envelope (the glazing) often needs to be sealed before interior trades—like drywall and flooring—can begin their work to avoid weather damage.

If the glazing installation stalls due to inaccurate drawings, it creates a bottleneck. The entire project timeline shifts to the right, leading to contractual penalties and delayed occupancy for the client.

Structural Failures

At its worst, a poor shop drawing can lead to structural failure. If the drawings specify the wrong type of anchor or fail to account for wind loads properly, the glazing system could detach or shatter under stress. This poses a severe safety risk to occupants and the public, leading to massive liability issues for the fabricators and installers.

Understanding the Glazing Shop Drawing Process

To appreciate the value provided by these services, it helps to understand the workflow involved in creating these essential documents.

1. Information Gathering and Analysis

The process begins with a thorough review of the architectural and structural plans. The drafting team gathers all relevant specifications, including wind load requirements, thermal performance goals, and aesthetic desires.

2. Drafting and Modeling

Using advanced CAD (Computer-Aided Design) software or BIM (Building Information Modeling) tools, the drafters create the shop drawings. This involves drawing the elevations, floor plans, and critical details (sections) of the glazing system.

During this phase, the drafter selects the specific aluminum profiles and glass types that meet the project requirements. They basically “build” the system digitally.

3. Review and Submittal

Once the initial drawings are complete, they are submitted to the architect and general contractor for review. This is an iterative process. The architect may mark up the drawings with corrections or questions regarding the design intent.

4. Revisions and Fabrication Release

The drafting team incorporates the architect’s comments and resubmits the drawings. Once the architect stamps the drawings as “Approved” or “Approved as Noted,” the project moves to the fabrication stage.

At this point, “take-offs” are generated—these are the lists of materials derived directly from the approved drawings that tell the factory exactly what to cut and assemble.

Building with Confidence and Precision

In the complex world of facade construction, glazing shop drawings are the roadmap to success. They are not merely an administrative hurdle but a fundamental tool for risk management and quality control.

By ensuring accuracy before fabrication begins, these drawings protect the budget, safeguard the schedule, and ensure the structural safety of the final installation. For fabricators and glazing contractors, partnering with Chudasama Outsourcing is the most effective way to guarantee that the architectural vision becomes a flawless reality.