In the food industry, handling waste efficiently and hygienically is a priority. Food processing plants deal with various types of waste, from food scraps to liquids, and each requires specialized handling equipment to ensure safety, sanitation, and smooth operations. Among the many options available, rotary lobe pumps stand out as one of the most efficient solutions for waste handling. But why should food plants opt for these specific pumps? In this article, we’ll explore the unique advantages of rotary lobe pumps and why they are an excellent choice for waste handling in food plants.

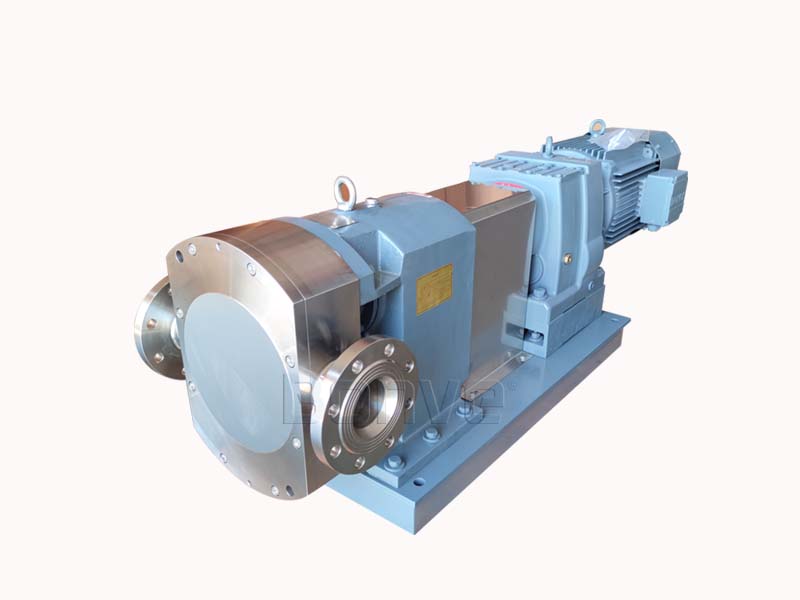

1. What is a Rotary Lobe Pump?

A rotary lobe pump is a positive displacement pump that moves fluids through the system by trapping a fixed volume of fluid between two lobes and pushing it through a discharge port. The two lobes rotate in opposite directions, creating a vacuum that draws the fluid into the pump. This type of pump is widely used in various industries, including the food and beverage sector, due to its unique ability to handle thick, viscous, or shear-sensitive fluids.

2. Rotary Lobe Pumps: Ideal for Food Waste Handling

Food waste, whether solid, semi-solid, or liquid, varies greatly depending on the type of food being processed. Rotary lobe pumps offer versatility in handling a broad range of waste products. From fruit and vegetable pulps to meat processing waste, these pumps can manage materials that would clog or damage other types of pumps. By using a rotary lobe pump, food plants can efficiently transfer waste materials without the risk of blockage, reducing maintenance and downtime.

3. Hygienic Design for Food Safety

One of the main concerns when handling food waste in processing plants is ensuring food safety and hygiene. Ace Lobe Pumps have designed their rotary lobe pumps with sanitation in mind. The smooth surface of the pump components prevents any material buildup, which is essential in preventing cross-contamination. These pumps can be easily cleaned and sanitized, ensuring that they comply with strict food safety standards.

Additionally, many rotary lobe pumps are designed with self-priming and dry-run capabilities, further enhancing their hygiene by minimizing the risk of bacterial growth that could occur from stagnant waste.

4. Energy Efficiency

Energy consumption is an important consideration for any manufacturing plant. Rotary lobe pumps are energy-efficient due to their low shear design. This means they require less energy to operate compared to other pump types, which can lead to substantial savings on electricity bills over time. For food plants dealing with high volumes of waste, the energy efficiency of these pumps can significantly reduce operational costs.

5. Rotary Lobe Pumps Can Handle High Viscosities

One of the standout features of rotary lobe pumps is their ability to pump highly viscous liquids. Waste generated in food plants often includes thick liquids, such as sauces, purees, or slurries, which can be difficult to pump using traditional methods. The rotary lobe pump excels in moving these types of waste without causing shear damage to the fluid, making it perfect for waste handling in food plants.

6. Durability and Long Lifespan

Another reason food plants should consider rotary lobe pumps for waste handling is their durability. Ace Lobe Pumps manufactures these pumps with high-quality materials that are resistant to wear and corrosion. Given that food waste handling involves continuous, often heavy-duty use, the long lifespan of a rotary lobe pump ensures a reliable solution that can withstand the demands of a busy food processing facility.

7. Low Maintenance Costs

Maintenance is a crucial aspect of any industrial operation. The design of the rotary lobe pump minimizes wear and tear on the pump components, which translates to fewer repairs and replacements. The ease of cleaning also means that rotary lobe pumps require less time and effort to maintain. For food processing plants, this means less downtime and lower overall maintenance costs.

8. Rotary Lobe Pumps Are Versatile and Flexible

Food plants often require a wide range of equipment that can handle different types of waste. Rotary lobe pumps offer exceptional versatility because they can handle a variety of materials. Whether the waste is liquid, sludgy, or semi-solid, rotary lobe pumps can be adapted to meet the specific needs of a food plant. This adaptability makes them an ideal solution for plants that process a wide range of food products.

9. Protecting the Environment

Waste disposal is a significant concern for food plants, as improper disposal of waste can lead to environmental pollution. Rotary lobe pumps help minimize waste spillage by efficiently moving fluids and slurries without leakage. These pumps are designed to be highly reliable in transferring food waste in a contained, controlled manner, reducing the likelihood of waste escaping into the environment.

10. Cost-Effective Long-Term Solution

While rotary lobe pumps may have a higher initial cost compared to some other types of pumps, the long-term benefits they provide far outweigh this initial investment. Due to their low maintenance requirements, energy efficiency, and long lifespan, rotary lobe pumps are a cost-effective solution for food plants that want to maximize their operational efficiency and minimize waste handling costs.

11. Reduced Downtime in Food Processing

Downtime in a food processing plant can lead to significant losses in productivity and profit. One of the key benefits of using rotary lobe pumps is their reliability in continuous operations. These pumps are designed to work without interruption, allowing the plant to maintain its flow of production without delays. Their robust design ensures that they perform optimally even under demanding conditions, making them a critical asset for food plants.

12. Easy Integration with Existing Systems

Rotary lobe pumps are also easy to integrate into existing food plant systems. Whether it’s adding a pump to an existing waste handling line or upgrading an older model, Ace Lobe Pumps ensures that their products can be seamlessly installed and configured. This ease of integration ensures that the transition to using rotary lobe pumps is hassle-free, allowing food plants to continue operating smoothly without significant disruptions.

13. How to Choose the Right Rotary Lobe Pump for Your Food Plant

Selecting the right rotary lobe pump for your food plant involves considering several factors, such as the type of waste you handle, the volume of waste, and the specific requirements of your plant. It’s essential to work with an experienced supplier like Ace Lobe Pumps, who can guide you through the process of choosing a pump that best fits your needs. Factors to consider include flow rate, pressure requirements, and the type of food waste that needs to be handled.

Conclusion

In conclusion, rotary lobe pumps are an ideal choice for food plants looking to handle waste efficiently, hygienically, and cost-effectively. Their versatility, durability, and low maintenance make them a reliable solution for handling a wide variety of food waste, from thick slurries to liquids. Whether you’re running a small-scale operation or a large food processing facility, investing in a rotary lobe pump from Ace Lobe Pumps will help streamline your waste handling processes, improve food safety, and reduce operational costs.