When considering crane safety, load charts, operator skill, and hook integrity, not to mention emergency stop routines, are sure to come to mind. Few think of the long black lines trailing along the girder or the compact battery tucked into a remote control. But here’s the truth: motion management and power reliability are the foundation under everything else.

A crane can be in perfect mechanical health yet fail at the worst moment if its cable system snags, twists, or sends unstable power. A highly trained operator is only effective if their controls stay powered without voltage dips, signal flaws, or sudden shutdowns. Two components that sit quietly in the background, solving those exact problems, include a properly installed Flatform cable for crane movement and reliable Ravioli Batteries for remote control systems.

Cable flow is a movement problem first, an electrical problem second

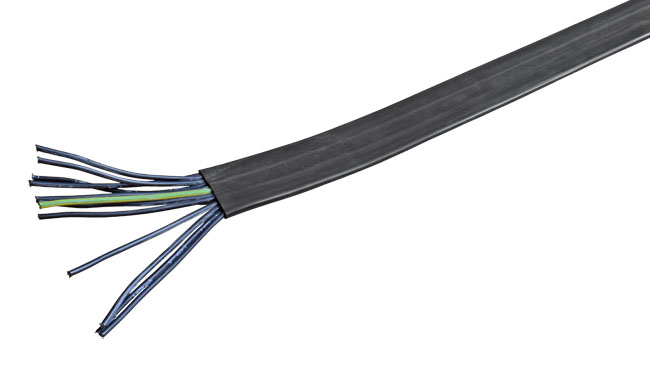

Overhead cranes move constantly in three directions, while the hoist and trolley do the lifting. The cable system is the nervous system, carrying uninterrupted electrical control and power signals. But should it tangle, stretch unevenly, kink, or rub against metal edges, the result isn’t just wear of its signal noise, power fluctuation, and eventually system failure.

This is why flat, flexible cables are commonly chosen for crane festoon systems instead of round trailing cables. A Flatform cable naturally stacks better, spreads mechanical stress evenly, and glides more predictably along the track. There’s no rotational torsion build-up, meaning less internal conductor fatigue and fewer weak points developing over time.

To the engineer who values durability, this marks the difference between a cable limping its way through several months and one which maintains structure and electrical performance through millions of cycles.

The dangers of bad cable behaviour on a live crane system

Crane cable faults do not gradually appear in a friendly, scheduled manner. They usually arise as sudden, costly, sometimes dangerous events:

- Unstable power delivery during trolley motion

- False signals due to internal conductor strain

- Intermittent disconnections, especially mid-travel

- Sudden stops or jolts

- Overheating at stress points

- Insulation wear due to uneven dragging or friction

- Premature system downtime

Downtime in industrial settings is not an inconvenience; it is a direct loss of productivity, a safety risk, and even a compliance issue in most cases.

Why a flat, layered cable design performs better in motion

The shape matters much more than what one assumes. A flat cable design offers:

- Lower bending stress during repeated motion

- Better stability on festoon systems

- Reduced twisting and internal strain

- Less conductor movement within the sheath

- Even-weight distribution for a smoother glide

- Improved electromagnetic stability during motion

For festoon systems and complex routings, a Flatform cable cuts down on stacking and twist issues; this reduces early conductor fatigue and unexpected signal noise.

Engineers sometimes overlook the impact of consistent motion control, but the data is clear: controlled, predictable movement extends cable lifespan, reduces heating, and stabilises electrical performance.

Power at height, control from the ground: the remote reliability layer

Modern cranes depend largely on radio remote controls. Operators are not constrained to a control station; they can move freely with better visibility, quicker decision-making, and safer load handling.

But a remote is only “remote” until its battery falters.

For industrial lifting, poor battery performance doesn’t just mean swapping a pack. It means:

- Delayed response times

- Loss of signal strength

- Mid-lift power warnings

- Forced work stoppage

- Increased risk of operational error

Power reliability in crane remotes is not a luxury; it’s a guarantee of control.

The role of Ravioli power systems in crane control

Ravioli is well-renowned in industrial crane electronics, particularly in radio remote control systems created for heavy-lift environments. Their control systems operate on dedicated rechargeable power packs, popularly referred to within the industry as Ravioli Batteries, designed to meet the power demands of their remote units.

Radio remote battery packs, normally sold as Ravioli Batteries or their authorised replacements, are matched to specific models of the radio remote. Confirm the chemistry and charge specifications to avoid mid-shift power faults.

Instead of going big on flashy tech, these power packs focus on three must-haves:

- Voltage stability to maintain signal transmission consistency

- Predictable discharge curves so controls do not die unpredictably

- Rechargeable form factors that fit industrial use cycles

Importantly, various battery chemistries could be used, depending on the model of a given remote, ranging from NiMH to Li-ion. Capacity, charging time, and environmental tolerance are model-dependent, meaning the correct type of batteries should always correspond to the type specified in the remote system.

Safety details most operators never get told

- Remote battery performance goes beyond uptime: it directly impacts safety behaviours.

- Reliable industrial remote power units often include:

- Low-voltage protection cut-offs

- Stable current delivery under load

- Overcharge protection in charging circuits

- Model-aligned casing and fit

- Predictable power decline instead of a sudden cut-off

That last point matters: Erratic battery failure forces split-second reactions from operators. A controlled, predictable low-power curve gives time to complete a lift safely or switch power without panic.

Cable and battery reliability in real crane scenarios

While the functions of cables and remote batteries are different, their failure modes often affect the same moments in crane operation.

| Scenario | Cable impact | Remote battery impact |

| Mid-travel power inconsistency | Causes voltage drop or signal noise | Causes weak remote transmission |

| Load at height | Sustaining steady current is a must | Sustaining steady radio link is a must |

| High-cycle environments or outdoor | Needs wear stability | Needs predictable recharge tolerance and discharge |

| Safety-critical operations | Must avoid kinks, static, and interruption | Must avoid sudden power loss |

The cost of neglecting these two “small” parts

Most crane failures are blamed on large, expensive parts. But operational data shows that the smallest components create the most frequent disruptions.

The true costs look like this:

- Unplanned line stoppages

- Emergency maintenance call-outs

- Replacement of second-tier parts damaged due to voltage instability

- Disrupted workflow sequencing

- Operational stress leading to human error

- Compliance risk in case of a lapse in safety consistency

- Higher long-term component turnover

A predictably behaving cable and a consistently powered remote remove one entire category of risks that could be avoided.

Conclusion: Reliability is not dramatic; failure is

A crane failure gets attention. The engineering choices that prevent it rarely do.

No operator praises a cable for running smoothly day in and day out. No supervisor celebrates a battery because it didn’t shut down mid-lift. But that’s the point: safety doesn’t announce its name. It proves itself through consistency.

Reliable movement, stable current, and predictable control are the real safety systems. Everything else sits on top of them.