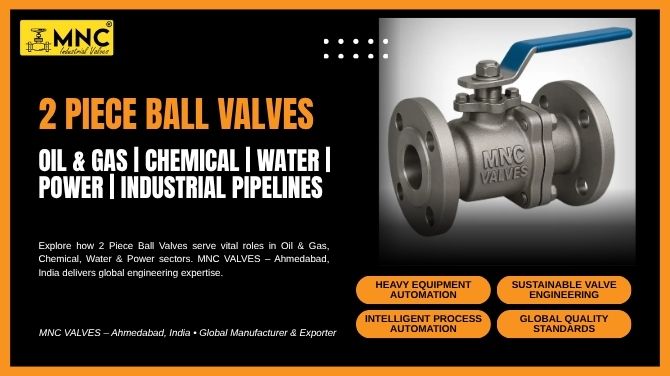

Because of its strong construction, long service life, automation compatibility, and leak-tight sealing, two-piece ball valves are the go-to shut-off option for oil and gas, chemical, water, electricity, and industrial pipelines. MNC VALVES, located in Ahmedabad, India, provides high-performance, globally certified two-piece valves for crucial applications.

Working Principle of 2 Piece Ball Valves – How They Deliver Reliable Shut-Off

A precisely machined spherical ball with a center bore powers a two-piece ball valve. The flow route either fully opens or seals when the actuator or lever spins the ball 90 degrees. Even with varying pressures, this quarter-turn mechanism guarantees quick actuation, low flow resistance, and tight shut-off.

The two-piece construction includes:

-

Body (Part-1) – connects to the pipeline

-

Body End Cap (Part-2) – contains the ball and seat assembly.

This design keeps the valve small and easy to maintain while guaranteeing simple disassembly for cleaning and seat replacement.

PTFE, RPTFE, or high-performance seats provide complete ball support, which reduces friction and maintains low operating torque—perfect for automation and continuous duty cycles.Design Features That Make 2 Piece Ball Valves Highly Preferred

Because they achieve the ideal mix between performance, cost effectiveness, and maintainability, 2-piece designs are preferred by modern industrial users. Important engineering characteristics consist of:

-

Quarter-turn operation for rapid shut-off in emergency and process-critical systems

-

Floating ball mechanism providing bubble-tight sealing (Class VI)

-

Anti-blowout stem improving safety in high-pressure lines

-

Low torque design supporting actuator mounting

-

Fire-safe design options for oil & gas applications

-

Full bore or reduced bore availability depending on flow needs

-

ISO 5211 mounting pad for direct actuator integration

-

High corrosion resistance via stainless steel grades

-

Threaded, welded, or flanged ends to match pipeline standards

Consistent performance in challenging temperature, pressure, and chemical environments is guaranteed by its high-efficiency design.

Material Options – Engineered for Diverse Industrial Media

A variety of materials are used in the production of two-piece ball valves to ensure media compatibility and application criticality.

-

WCB / A105 Carbon Steel – ideal for oil, gas, steam, and high-pressure systems

-

CF8 / SS304 Stainless Steel – suitable for water, food, beverage, and neutral media

-

CF8M / SS316 Stainless Steel – preferred for chemical, petrochemical, and corrosive services

-

Duplex / Super Duplex – used in offshore and marine applications

-

Bronze / Gunmetal – for seawater and marine pipelines

Depending on process temperature and chemical exposure, seat and seal alternatives include PTFE, RPTFE, CFT, PEEK, Viton, NBR, and Graphite.

Pressure Ratings, Testing & Global Standards Compliance

2-piece ball valves from MNC VALVES adhere to stringent global engineering standards including:

-

API 598 (Valve Testing)

-

API 6D / API 607 (Fire-Safe)

-

ASME B16.34 (Pressure-Temperature Ratings)

-

EN / ISO Standards

-

BS 5351

Typical pressure ranges include:

-

Class 150 / Class 300 / Class 600

-

PN16 / PN25 / PN40

-

High-pressure threaded valves up to 1000 PSI / 1500 PSI / 3000 PSI

Each valve undergoes shell test, seat leakage test, hydrostatic test, and pneumatic test before dispatch, ensuring long-term durability and zero failure in field conditions.

Applications Across Major Industries – Why Every Sector Depends on 2 Piece Ball Valves

Oil & Gas – High Integrity, Fire-Safe, Critical Shut-Off Valves

Two-piece ball valves are used in petroleum pipelines, natural gas distribution networks, oil refineries, and upstream drilling rigs because of its durable design and fire safety. They resist hydrocarbon corrosion, provide safe shut-off under volatile flow circumstances, and function dependably during extreme temperature and pressure cycles.

Chemical & Petrochemical – Resistant to Corrosive Media

Toxic fluids, solvents, polymers, and strong acids are all handled by chemical facilities. In reaction lines, transfer systems, and storage terminals, SS316 and exotic alloy two-piece valves are essential due to their excellent corrosion resistance, negligible leakage, and adherence to stringent safety regulations.

Water & Wastewater – Reliable Flow Control for Large Pipelines

These valves offer long service life, little maintenance, and seamless operation for everything from municipal water networks to wastewater treatment plants. Their full-bore designs increase pumping efficiency by reducing pressure drop.

Power Generation – Robust Under Steam & High Temperature Cycles

Power plants are subject to varying thermal demands. Reliable generation uptime is ensured by carbon steel and alloy steel two-piece valves that can handle superheated steam, condensate, and high-pressure feedwater lines.

HVAC & Building Services – Smooth Operation & Zero Leakage

These valves are used for chilled water, hot water, compressed air, and glycol lines in commercial buildings, industrial facilities, and HVAC systems because they are simple to operate and require little upkeep.

Pharmaceutical & Food Industry – Hygienic & Cleanable Designs

Contamination-free operation is guaranteed by two-piece stainless steel valves. They are appropriate for pharmaceutical reactors, dairy processing, beverage lines, and edible oil systems due to their smooth internals, crevice-free design, and CIP/SIP compatibility.

Marine & Offshore – High Strength & Saltwater Resistance

Desalination facilities, shipbuilding, and offshore platforms rely on duplex and bronze two-piece valves that can endure severe ocean conditions and corrosion caused by chloride.

Steel, Cement & Mining – Rugged for Abrasive & Slurry Duties

Because of its excellent mechanical strength and capacity to manage suspended materials, two-piece valves are utilized in coolant, lubrication, gas purging, and dust collection systems.

Key Benefits of 2 Piece Ball Valves for Modern Industries

-

High flow capacity with minimal pressure drop

-

Bubble-tight shut-off for safety-critical operations

-

Short actuation time for rapid emergency isolation

-

Long operating life with minimal maintenance

-

Compatibility with pneumatic, electric & hydraulic actuators

-

Cost-effective design compared to multi-piece valves

-

Ease of installation and quick seat replacement

-

Available in wide range of MOCs and end connections

-

Suitable for clean, corrosive, viscous & high-pressure media

This blend of performance, reliability, and value makes them a global industry favourite.

MNC VALVES – Leading Manufacturer of 2 Piece Ball Valves in Ahmedabad, India

Precision Engineering, Global Standards & Export-Grade Manufacturing

MNC VALVES is a reputable industrial valve manufacturer that produces 2-piece ball valves of worldwide grade that are designed to withstand challenging operating conditions. The company produces valves that satisfy API, ASME, ANSI, EN, DIN, and ISO standards thanks to sophisticated CNC machining, internal testing, metallurgy control, and stringent QA procedures.

Our manufacturing strengths include:

-

WCB, CF8, CF8M, A105, and Duplex grade production

-

CNC machining with micrometer-level tolerances

-

Advanced hydro/pneumatic test rigs

-

ISO-compliant quality systems

-

Precision seat/ball finishing for zero leakage

-

Actuator-ready designs with ISO 5211 mounting pads

-

Export-ready packaging and documentation

We service EPC contractors, OEMs, refineries, chemical plants, utilities, and manufacturing facilities in India, the Middle East, Africa, Southeast Asia, and Europe.

Conclusion & Strong CTA – Partner with MNC VALVES for Reliable Industrial Solutions

Because they provide unparalleled sealing performance, durability, safety, and automation compatibility across oil and gas, chemicals, water, power, marine, food, pharma, and process applications, two-piece ball valves continue to be the foundation of industrial pipe systems worldwide. Leading the way in technical excellence, MNC VALVES, Ahmedabad, provides world-class manufacture, compliance with international standards, and reliable supply guarantees.