The automotive industry is undergoing rapid transformation, driven by technological advancements, new consumer demands, and a push towards sustainability. One of the most revolutionary technologies making waves in automotive manufacturing is 3D printing. Also known as additive manufacturing, 3D printing allows manufacturers to create intricate parts and prototypes with a level of precision and efficiency previously unimaginable. As the automotive sector explores this technology, it’s important to understand its benefits, challenges, and the significant role it plays in shaping the future of vehicle design, production, and aftermarket services.

In this article, we will explore the impact of 3D printing in the automotive industry, examining its applications, advantages, potential obstacles, and the implications for the industry’s future. From reducing costs to enabling greater design flexibility, 3D printing is set to revolutionize how vehicles are designed, produced, and repaired. Understanding the key aspects of this technology can help automotive professionals stay ahead of the curve and leverage its full potential.

The Basics of 3D Printing in the Automotive Industry

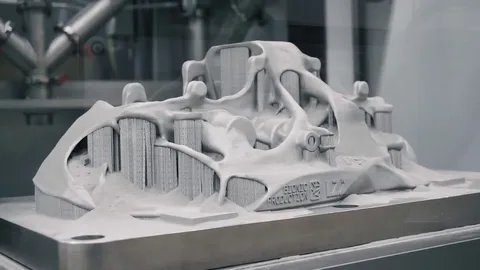

3D printing, also known as additive manufacturing, involves creating objects layer by layer from a digital model. Unlike traditional manufacturing methods that often require molds, dies, or complex tooling, 3D printing builds components directly from a 3D file. The ability to design and create parts without the constraints of conventional manufacturing is one of the most appealing aspects of this technology. In the 3D Printing in Automotive Industry has become an essential tool for prototyping, low-volume production, and even custom parts manufacturing.

For automotive manufacturers, 3D printing offers a range of possibilities. The most common applications include the production of prototypes, custom car parts, and even tooling used in the production process. This ability to quickly iterate designs and produce functional parts can drastically reduce development timelines and costs. For example, instead of waiting for months for a new tool to be created, 3D printing can make prototypes or functional parts in days, speeding up the entire design and production process.

How 3D Printing is Revolutionizing Prototyping and Design

Prototyping is one of the earliest applications of 3D printing in the automotive industry, and for good reason. Traditional prototyping methods can be expensive and time-consuming, as they often require the creation of molds, dies, and tooling. With 3D printing, automotive designers can create highly accurate, functional prototypes at a fraction of the cost and time. This leads to faster design iterations and allows for more innovative and complex designs that would be difficult or impossible to produce using traditional methods.

Moreover, 3D printing enables an unprecedented level of customization in the automotive industry. Manufacturers can quickly print unique components tailored to specific design requirements. Whether it’s a custom interior part for luxury cars, a unique dashboard design, or an experimental structural component, 3D printing offers designers a level of flexibility that traditional manufacturing cannot match. This capability is crucial in today’s competitive automotive market, where differentiation and innovation can be key drivers of success.

Cost Reduction and Efficiency with 3D Printing in Manufacturing

One of the primary benefits of 3D printing in the automotive industry is the potential for cost reduction, especially in the production of complex or low-volume parts. Traditional automotive manufacturing often requires expensive molds, dies, and tools, which can be costly to design, produce, and maintain. Additionally, any mistakes made during production can lead to significant costs due to the need for rework or even the creation of new tools. 3D printing eliminates many of these upfront costs by allowing manufacturers to directly print parts from digital designs.

In addition to the initial cost savings, 3D printing also improves manufacturing efficiency. The ability to print spare parts and components on-demand reduces the need for large inventories, which can save money in warehousing and logistics. With just-in-time production, manufacturers can produce parts as needed without overstocking, further streamlining operations. Moreover, 3D printing can significantly reduce material waste, as parts are built layer by layer, and excess material is minimal compared to traditional subtractive manufacturing methods.

The Impact of 3D Printing on Automotive Parts and Aftermarket Services

3D printing in the automotive industry is not just limited to manufacturing new cars; it also has a significant impact on the aftermarket parts sector. The ability to create custom or replacement parts on-demand is particularly beneficial for older vehicle models, which may no longer have readily available parts in the market. Instead of searching for rare components or relying on costly part replacements, car owners can turn to 3D printing to produce the exact parts they need.

This is particularly beneficial for smaller vehicle repair shops, who may not have the resources to stock a wide range of parts. By using 3D printing, these shops can produce parts in-house, reducing wait times and costs for customers. In some cases, manufacturers are even beginning to offer digital blueprints for customers to print their own replacement parts at home or through local service providers. This shift could lead to a more decentralized and customer-centric aftermarket services model, changing the way parts are sourced and repaired in the automotive world.

The Challenges and Future of 3D Printing in Automotive Manufacturing

While the benefits of 3D printing in the automotive industry are clear, the technology is not without its challenges. One of the biggest obstacles is the speed of production. Currently, 3D printing is slower than traditional manufacturing methods, especially for large-scale production. This makes it less ideal for mass production, where speed and efficiency are paramount. However, as 3D printing technology continues to improve, it is expected that production times will decrease, making it a viable option for mass manufacturing.

Additionally, material limitations still present a challenge. While a wide variety of materials can be used in 3D printing, including plastics, metals, and composites, they may not always meet the same durability or performance standards as traditionally manufactured parts. Advances in material science are expected to overcome this barrier, allowing for the creation of more robust and high-performance parts using 3D printing. The future of 3D printing in the automotive industry looks promising, and as technology continues to evolve, it is likely that it will become an even more integral part of automotive manufacturing and aftermarket services.

Conclusion

3D printing in the automotive industry is transforming how vehicles are designed, produced, and repaired. With its ability to reduce costs, streamline production, and enable complex designs, 3D printing is poised to play a crucial role in the future of automotive manufacturing. While there are still challenges to overcome, such as production speed and material limitations, the technology is rapidly evolving, and its potential is enormous.

From prototyping and design to custom and aftermarket parts production, 3D printing is reshaping the automotive landscape. As manufacturers and service providers continue to explore its capabilities, it’s clear that 3D printing will remain at the forefront of innovation in the automotive industry. For those in the sector, staying informed about the latest advancements in 3D printing technology will be key to maintaining a competitive edge and ensuring long-term success in an increasingly fast-paced and tech-driven market.