A radius gauge helps measure curved edges accurately in workshops. Learn its uses, least count, sizes, and sets in simple and easy language

What Is a Radius Gauge?

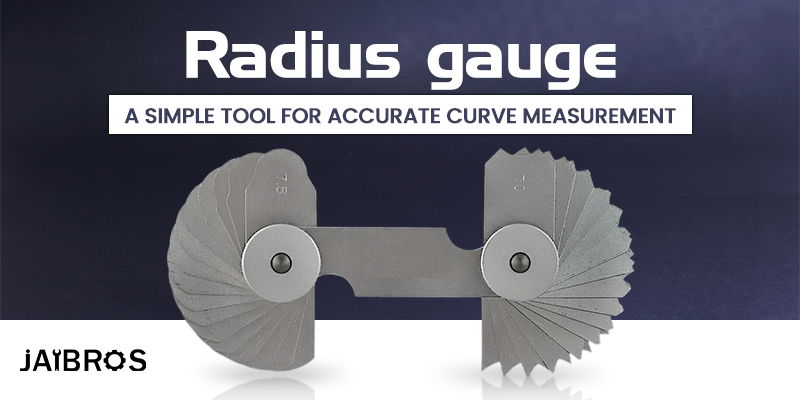

A radius gauge is a hand tool used to measure or check the radius of curved surfaces. It does not give digital readings but helps compare the curve of a part with a known radius size. The tool has many thin metal leaves, and each leaf has a different curved shape with a marked radius value.

This gauge is mostly used to check fillets, round edges, grooves, and curved corners on metal, plastic, or wooden parts. It is useful during machining, fitting, and final inspection work. Because of its simple design, even beginners can use it with confidence.

Why This Tool Is Important in Workshops

Curved surfaces are common in shafts, flanges, dies, moulds, and machine parts. If the radius is incorrect, parts may not fit properly or may wear out faster. This gauge helps avoid such problems by allowing quick checking during and after machining.

It also saves time. Instead of using complex measuring machines, workers can instantly match the curve with the correct leaf. This makes the tool very useful in daily workshop work.

Radius Gauge Least Count Explained

The least count of a radius gauge depends on the smallest radius value marked on its leaves. Most standard gauges have leaves starting from 1 mm or 1/64 inch, depending on whether the set is metric or imperial.

For example, if the smallest leaf is 1 mm, then the least count is 1 mm. This means the tool can check radius values in steps of 1 mm. Some fine sets offer smaller steps for better accuracy. Even though it is a comparison tool, correct handling gives very close and practical results.

Radius Gauge Specifications

The specifications of this tool define its quality, accuracy, and usability. Most gauges are made from hardened stainless steel or spring steel. This gives strength, rust resistance, and long life.

Each leaf is clearly marked with its radius size. The leaves are smooth and thin, allowing them to fit closely against curved surfaces. The edges are finely finished so they do not damage the job surface. Good quality tools follow standard measurement norms, making them reliable for inspection use.

Radius Gauge Set Types

A radius gauge usually comes as a set rather than a single piece. A standard set contains multiple leaves joined by a screw or rivet. These sets are available in two main types: internal and external.

Internal sets are used to check concave curves, like grooves or inner corners. External sets are used for convex curves, like rounded edges or shafts. Some combined sets include both types in one box, making them more versatile for workshop use.

Radius Gauge Size Options

Radius gauge size refers to the range of radius values included in the set. Common metric sets cover ranges like 1 mm to 25 mm. Imperial sets may range from 1/64 inch to 1 inch.

The size you choose depends on your work. Small radius sizes are used in precision parts and tool making. Larger sizes are useful in fabrication and general machining. Having a wider size range gives more flexibility and reduces the need for multiple tools.

How to Use a Radius Gauge Correctly

Using this tool is simple. First, clean the surface of the job and the gauge leaf. Select a leaf that looks close to the curve you want to check. Place it against the curve and see if it fits without any gap or light showing.

If the leaf matches perfectly, the marked value is the radius of that surface. If not, try the next higher or lower size until you get a perfect fit. Proper lighting helps in checking accuracy.

Care and Maintenance Tips

To keep your radius gauge accurate, always store it in its case after use. Clean it with a dry cloth to remove oil or dust. Do not bend the leaves, as this can affect accuracy. Avoid dropping the tool on hard surfaces.

Regular care ensures long life and reliable measurements. A well-maintained tool gives consistent results for many years.

Choosing the Right Tool Supplier

Buying quality measuring tools is very important for accuracy and safety. Trusted industrial suppliers offer tools that meet workshop standards and last longer. Platforms like Jaibros provide a wide range of measuring instruments suitable for Indian workshops, training centres, and industrial use. Choosing the right supplier ensures you get durable tools with clear markings and proper finish.

Frequently Asked Questions (FAQs)

Q1: What is a radius gauge used for?

A radius gauge is used to check and measure the radius of curved or rounded surfaces on a part. It helps match internal and external curves during machining, fitting, and inspection work. This ensures proper shape, correct fitting, and good surface finish.

Q2: What is the least count of a radius gauge?

The least count of a radius gauge depends on the smallest radius marked on its leaves. In most metric sets, it is 1 mm, while inch sets usually start from 1/64 inch.

Q3: Are radius gauge sets available in metric and inch sizes?

Yes, radius gauge sets are available in both metric and inch sizes. Metric sets are commonly used in India, while inch sets are used where imperial measurements are required.

Q4: Can beginners use this tool easily?

Yes, beginners can use this tool easily. It is simple to handle and works by matching the gauge leaf to the curve, so no special training or complex calculations are needed.

Q5: How should a radius gauge be stored?

A radius gauge should be cleaned after use and stored in its protective case. This prevents dust, rust, and bending of the leaves, helping maintain accuracy and long service life.

Conclusion

Accurate measurement is the base of good workmanship. A radius gauge is a simple yet powerful tool that helps check curved surfaces quickly and correctly. Understanding its least count, specifications, set types, and size options helps you choose the right one for your work.

Whether you are a machinist, fitter, student, or quality inspector, this tool makes your job easier and more accurate. With proper use and care, it becomes a valuable part of any workshop.