Precision-engineered valves are essential to maintaining effective fluid management and safety in a variety of industries within India’s dynamic industrial landscape. One of the most well-known brands in this field is MNC VALVES, a reputable valve manufacturer in Ahmedabad, India, renowned for its exceptional quality, inventiveness, and dependable operation. MNC VALVES has established itself as a valued partner for sectors needing long-lasting and high-performing flow control systems thanks to years of manufacturing expertise.

An extensive selection of industrial valves

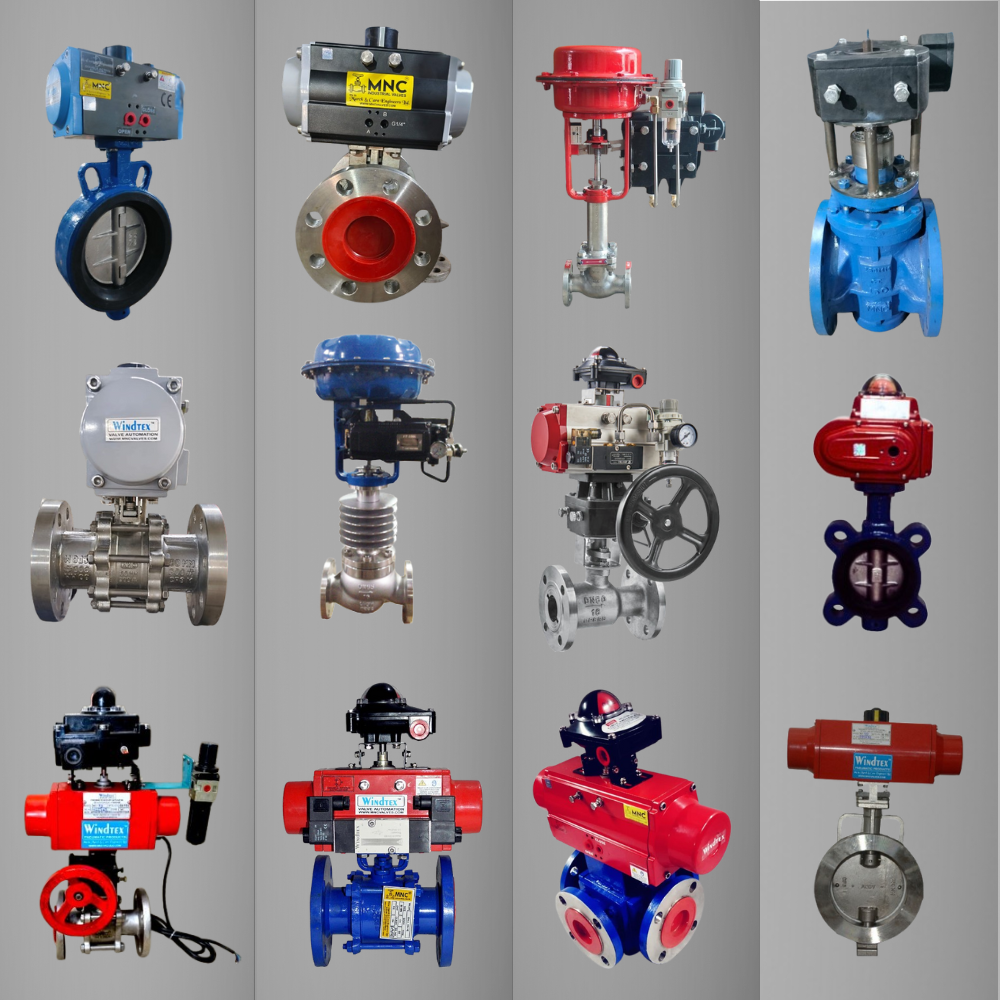

A large selection of industrial valves designed to satisfy demanding applications is available from MNC VALVES. Every type of valve is made to last a long time, function at its best, and require little maintenance.

- Ball Valves: MNC VALVES are made to close quickly and tightly. The chemical, oil, and gas sectors are the perfect fit for ball valves. They come in full and reduced bore versions and are offered in single-, two-, and three-piece configurations. Excellent corrosion resistance, low torque, and smooth operation are guaranteed by the sturdy design.

- Gate Valves: Made for on-off operation, MNC VALVES’ gate valves offer a complete flow channel with less pressure drop. They are ideal for steam, petrochemical, and water treatment applications. For a range of installation requirements, the valves come with both rising and non-rising stem options.

- Globe Valves: Globe Valves are made to control pipeline flow. Globe valves made by MNC VALVES have excellent seating surfaces and precise machining, guaranteeing long-term dependability and leak-tight operation. For throttling applications in the power, oil, and chemical industries, these valves are perfect.

- Butterfly Valves: Used extensively in chemical processing, HVAC, and water systems, butterfly valves are inexpensive and lightweight. Wafer and lug type butterfly valves from MNC VALVES come with manual, gear, or pneumatic actuators for versatile control and superior sealing capabilities.

- Non-return valves: Examine the . In piping systems, valves are crucial for preventing backflow. Swing, lift, and dual plate check valves are produced by MNC VALVES to preserve the integrity of the flow direction and guard against possible harm to pumps and compressors.

- Control Valves: MNC VALVES’ Control Valves provide unparalleled accuracy for process control systems that need precise flow regulation. These valves are designed to manage different flow and pressure situations in sectors including oil refining, chemicals, and pharmaceuticals.

- Strainer Valves: By removing impurities and debris, strainers protect pipeline equipment. MNC VALVES provides Y-type and basket-type strainers for steam, oil, and water lines that are designed to last and be simple to maintain.

Superior Materials and Superior Engineering

Premium materials including SS304, SS316, CF8, and CF8M are used by MNC VALVES to construct their valves, guaranteeing superior mechanical strength and resistance to corrosion. These stainless steel grades have a longer service life and are appropriate for severe conditions and aggressive media.

- SS304: renowned for its excellent weld ability and overall resistance to corrosion.

- SS316: Molybdenum is added to SS316 to improve its resistance to acids and chlorides.

- CF8/CF8M: Cast substitutes for SS304 and SS316 that are perfect for essential fluid applications and parts that hold pressure.

To guarantee consistent performance, each valve is subjected to precise machining, precise assembly, and hydrostatic testing. In order to ensure interoperability with worldwide piping systems, the flanged, screwed, and welded end connectors adhere to international standards including ANSI, ASME, DIN, and BS.

Principle of Design and Operation

MNC VALVES produces valves that are made to operate smoothly, leak little, and lose little pressure.

- For fast cut-off, ball and gate valves use a linear motion mechanism.

- Globe and Control Valves use a disc or plug movement to give variable flow control.

- Butterfly Valves regulate flow in a compact and effective manner by using a revolving disc.

- Without human assistance, check valves automatically stop reverse flow.

- Strainers catch undesired solids to safeguard downstream equipment.

To guarantee optimal uptime in industrial systems, the company concentrates on ergonomic designs, long-lasting seals, and simple maintenance.

Sectors MNC Valves Serves

MNC VALVES serves a variety of sectors that depend on safe and accurate fluid handling, including:

- Oil & Gas: Refinery and pipeline high-pressure, corrosion-resistant valves.

- Petrochemical: Process fluids and strong chemicals are handled by these valves.

- Water Treatment: Filtration and distribution systems with smooth-flowing valves.

- Chemical & Pharma: sanitary, leak-proof valves that are appropriate for clean settings.

- Steel & Power: Sturdy valves that can tolerate high temperatures and pressures.

- Paper & Textile: Sturdy steam and process water control valves.

Every product is designed to satisfy particular industrial needs, guaranteeing effective operation even in the most demanding situations.

Dedication to Dependability and Quality

The manufacturing philosophy of MNC VALVES is based on quality assurance. Every valve undergoes rigorous testing to ensure that it satisfies ISO, API, and IBR requirements, starting with raw material inspection and ending with final testing. To ensure endurance and dimensional correctness, the organization uses automated testing methods, CNC technology, and state-of-the-art machining machines.

To make sure each valve operates dependably in real-world field settings, corrosion-resistant coatings, leak testing, and pressure endurance testing are also carried out.

Why Opt for MNC Valve Products?

- decades of manufacturing and design experience with valves.

- large selection of industrial valves for various industries.

- use of high-quality materials (CF8, CF8M, SS304, SS316).

- adherence to quality standards and international standards.

- sophisticated machining, finishing, and testing procedures.

- Fast delivery and affordable prices.

- trusted by industries both domestically and internationally.

As one of the Top Valve Manufacturing Companies in India, MNC VALVES maintains its industry leadership by placing a high priority on engineering precision, customer satisfaction, and innovation.

Contact Information

MNC VALVES

Leading Industrial Valve Manufacturer in Ahmedabad, India

Address: Ahmedabad, Gujarat, India

Contact: +91-8851787886

Website: www.mncvalves.com

Email: sales@mncvalves.com

Read More About

Click Here