Manufacturing accuracy and efficiency are more important than ever in today’s highly competitive industrial landscape. One of the most revolutionary innovations driving this progress is automated material positioning. By utilizing this advanced technology, manufacturers can maximize workflow, reduce waste, and ensure exceptional levels of precision throughout the production process. As the demand for faster, smarter, and more cost-effective manufacturing methods grows, automated material positioning is clearly emerging as a foundational technology transforming the modern factory floor.

Greater Efficiency and Production Speed

The notable benefit of automated material positioning is the much faster manufacturing speed. Often depending on manual measuring, setup, and adjustment—which can be time-consuming and prone to mistakes—traditional techniques might Conversely, automated systems automatically align and place items with minimum human involvement, therefore simplifying these chores.

By freeing operators from more manual labor, this helps them to concentrate on higher-level activities, therefore improving the general productivity. The system’s fast and exact material repositioning ability not only lowers downtime but also speeds cycle times. Faster manufacturing rates resulting from this help firms to satisfy customer needs and strict deadlines without compromising quality.

Improved Accuracy and Precision

Especially in sectors including aircraft, automotive, and electronics, where even little deviations can cause product failure, manufacturing parts to exact specifications is absolutely crucial. Leveraging sensors, algorithms, and mechanical actuators that regularly position materials with great precision, automated material positioning guarantees repeatable, pinpoint accuracy.

Manufacturers can create parts with closer tolerances by removing the potential of human mistake in the measuring and setup process. This higher degree of accuracy not only improves product quality but also lessens the need for rework and material waste, therefore saving significant costs over time.

Labor Cost Cutting

Although purchasing automated equipment could seem expensive initially, the long-term labor cost savings are really significant. Automated material positioning reduces the need for technical and repeated positioning chores depending on trained manpower. Companies can focus their personnel toward more value-added activities since less workers are required to run machines.

Automation also lessens the new hire training load. Once a system is programmed, it guarantees constant performance independent of operator skill level, therefore guaranteeing standardized results with every use. This streamlines onboarding and lets companies keep output even in lean times.

Enhanced Working Safety

Any production setting should give workplace injuries first priority, particularly in relation to sharp tools and heavy materials. By lowering the requirement for operators to personally handle or change materials close to cutting or shaping tools, automated material positioning helps reduce these hazards.

Built-in safety elements include collision detection, light curtains, and emergency stops abound in many systems. Manufacturers can preserve a safer workplace and lower the frequency of work-related injuries by keeping employees at a safer distance from machinery and limiting their physical contact with risky components.

RazorGage Positioner’s Function in Integration with Advanced Equipment

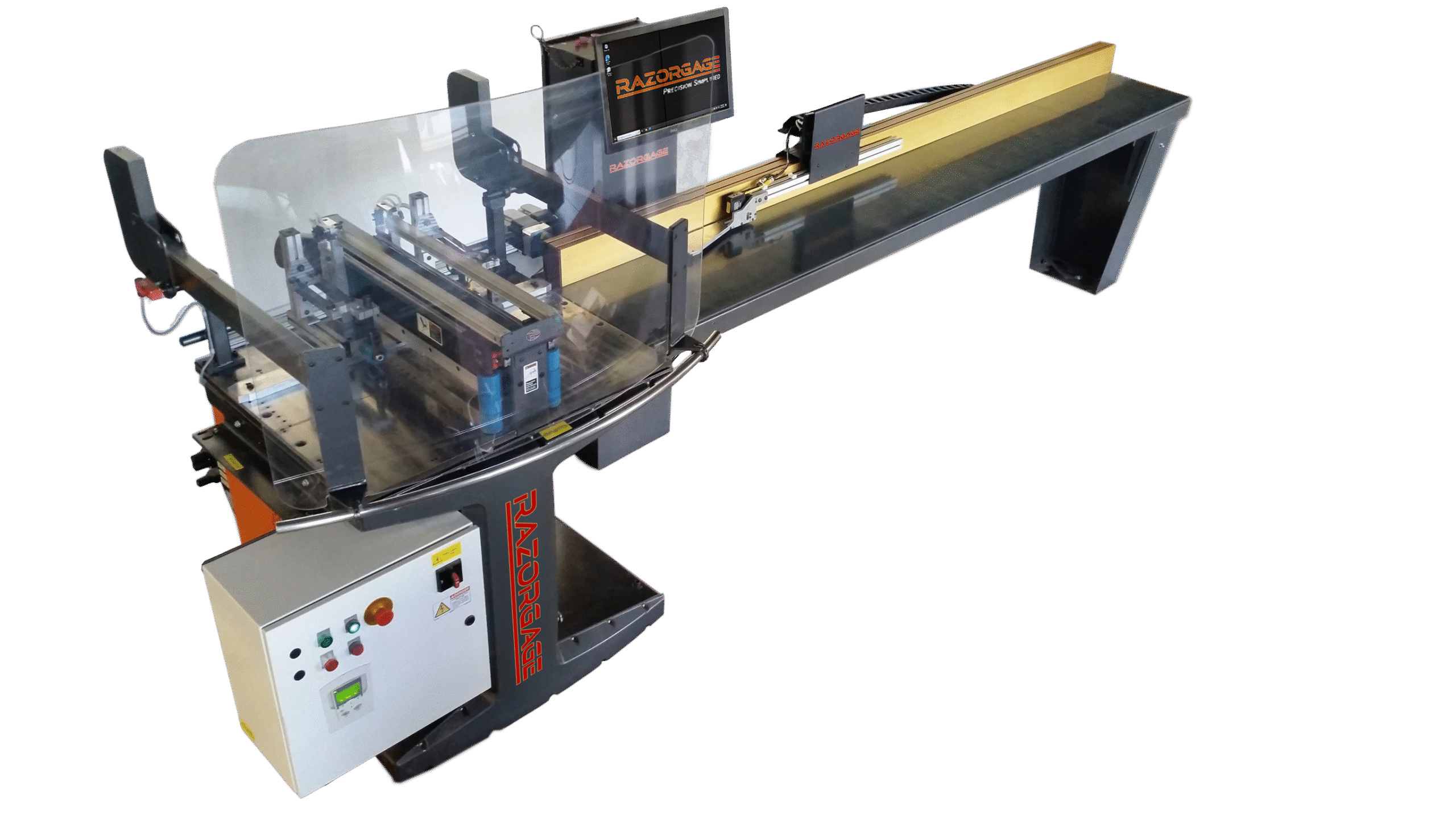

To remain competitive, modern companies depend more and more on high-tech solutions; the RazorGage Positioner is a perfect illustration of this creativity in action. Designed to automatically move and place components, RazorGage is an intelligent positioning device that easily connects with cutting, drilling, and assembly tools.

Renowned for its robustness and fast running speed, the RazorGage Positioner blends clever software controls with exact servo-driven actuation. It lets users enter dimensions electronically and let the system handle precise material placement free from repeated measurement or guesswork.

This degree of integration lowers material waste and considerably increases output. Features that help to create an overall leaner and smarter production system include operators’ easy memory of past settings, modify lengths on demand, and even batch-process several tasks with varying requirements. Manufacturers may future-proof their processes and fully enjoy automated material positioning by using instruments like the RazorGage Positioner.

Scalability And Flexibility

Automated material positioning also has great versatility. From woodworking and metal fabrication to plastics and composites, these systems can be tuned to fit many kinds of production uses. Automated systems can be adjusted to fit various material types, sizes, and handling requirements whether your project involves lengthy beams, sheets, or cylindrical components.

Moreover, automated systems can be simply scaled or reprogrammed when production needs change or rise. This flexibility guarantees that producers may react fast to changes in product design or order volume without making totally new equipment investments. Expanding capabilities over time is simpler with the modularity and upgrade options many systems, including the RazorGage, offer.

Regularity and Repeatability

Consistency is fundamental in production. Automated material positioning guarantees exactly like last every cut, hole, or bend. Large-scale manufacturing in particular depends on this repeatability since variances could cause assembly mistakes, inadequate fit, or functional faults of the final product.

Programming material dimensions and positioning sequences into the technology allows producers to replicate intricate designs and patterns across hundreds of thousands of units exactly without variation. By guaranteeing consistent results, this not only increases product consistency but also customer happiness.

Process Optimization And Data Collecting

Digital interfaces and connectivity tools included into modern automated systems let producers get real-time data on machine performance, positioning accuracy, material use, and cycle times. For efforts at ongoing improvement, this information can be quite helpful.

Analyzing performance measures and trends helps businesses to spot problems, monitor maintenance requirements, and streamline processes for maximum throughput. Integration with Industry 4.0 technology improves these advantages even more by allowing predictive maintenance, remote diagnostics, and adaptive learning systems that over time fine-tune performance.

Environment Advantages

Natural reduction of waste follows from efficient use of resources. Perfect alignment reduces the need for rework or thrown-away parts. By reducing resource use, this not only saves money but also helps environmental goals.

Because of positioning mistakes, automated methods also cut the energy used in reprocessing or handling of materials. Smart scheduling and load balancing taken together will clearly reduce the total energy footprint of a manufacturing process.

Final Thought

Manufacturers trying to increase efficiency, accuracy, and profitability should strategically move toward automated material positioning—not just a trend, but a necessity. Modern manufacturers are quickly realizing why this technology is becoming indispensable. With tools like the RazorGage Positioner, benefits such as shorter production times, reduced labor costs, enhanced safety, and greater sustainability are more accessible than ever—making it a game-changer on the factory floor.

Tools like the RazorGage Positioner show how clever positioning systems might improve manufacturing processes to unprecedented degrees. Whether your business is a big industrial plant or a small workshop, adopting automated material positioning can be the secret to remain nimble, competitive, and future-ready in a changing environment.