In most industrial plants, pumps are the beating heart of the system. Whether you are in power generation, oil & gas, chemicals, or water treatment, pumps ensure that fluids move reliably through the process. But pumps, especially centrifugal pumps, are sensitive machines. They need a minimum flow of liquid at all times to stay healthy.

When a pump runs at low flow or no flow, several problems can occur—overheating, cavitation, seal failure, vibrations, and even permanent damage. To prevent such costly issues, industries rely on Automatic Recirculation Valves (ARVs).

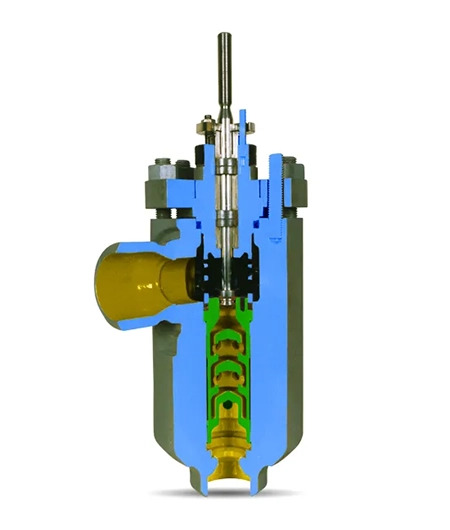

An Automatic Recirculation Valve (ARV valve) is a special type of valve designed to protect pumps by ensuring that the minimum flow is always maintained. Even when process demand decreases, the ARV automatically redirects excess flow back to the suction tank or another safe return line. This makes sure the pump never runs dry and always operates in a safe range.

In this article, we will explain the top benefits of installing Automatic Recirculation Valves in your plant, along with why they are so important in industrial systems.

What is an Automatic Recirculation Valve?

Before jumping into the benefits, let’s understand how an Automatic Recirculation Valve works in simple terms.

Think of a pump like a car engine. If you run an engine without coolant, it overheats and breaks down. Similarly, if you run a pump without enough flow, it gets damaged. The ARV valve acts like a safety device that automatically keeps “coolant” (fluid) circulating through the pump.

When the main process line requires full flow, the ARV stays open to deliver liquid where it’s needed. But when demand reduces, the ARV automatically opens a bypass line, sending excess liquid back to the tank. This way, the pump always gets the minimum flow required for safe operation.

In short:

-

Normal flow → Fluid goes to process line.

-

Low flow → Fluid is recirculated automatically.

This automatic action protects the pump without any manual intervention or complex control systems.

Top Benefits of Automatic Recirculation Valves

Now let’s explore why ARVs are so widely used in industries and how they can benefit your plant.

1. Pump Protection from Low-Flow Damage

One of the most important functions of an ARV valve is to prevent pump damage under low-flow conditions.

-

Without ARVs: Pumps can overheat, cavitate, and suffer from vibrations and wear.

-

With ARVs: The minimum required flow is always guaranteed, keeping pumps safe and reliable.

This protection is especially critical for high-pressure pumps such as boiler feed pumps, which are extremely sensitive to flow conditions.

2. Automatic and Self-Operated

Unlike other solutions that need sensors, flow meters, and controllers, an Automatic Recirculation Valve works entirely on its own.

It automatically senses when the main flow drops and opens the bypass line. This means:

-

No need for operators to intervene.

-

No dependency on power supply or electronics.

-

Reduced complexity and increased reliability.

For industries running 24/7 operations, this automation provides peace of mind.

3. Energy Efficiency and Stable Operations

When pumps run under correct conditions, they consume less energy and operate more efficiently.

An ARV valve helps by:

-

Preventing wasted energy from low-flow operation.

-

Ensuring steady pump performance.

-

Reducing wear and tear, which keeps efficiency high over time.

Even though an ARV doesn’t directly save energy like a VFD (Variable Frequency Drive), it maintains overall stability and reduces hidden energy losses caused by improper pump operation.

4. Extended Equipment Life

Replacing or repairing pumps is not only expensive but also causes downtime in production. By protecting pumps from running dry or overheating, Automatic Recirculation Valves extend the lifespan of critical equipment.

Less stress on pumps = fewer breakdowns = longer life cycle.

This translates into long-term cost savings and better return on investment.

5. Reduced Maintenance Costs

Maintenance costs are one of the biggest expenses in industrial plants. Pump repairs, seal replacements, and impeller damage can quickly add up.

With an ARV valve installed, these issues are minimized because the pump is always operating in safe conditions. This reduces:

-

Unplanned maintenance.

-

Spare parts replacement.

-

Manpower requirements for repairs.

In the long run, ARVs pay for themselves by preventing expensive failures.

6. Versatile Applications Across Industries

Automatic Recirculation Valves are used in almost every industry where pumps handle liquids under varying demand conditions. Some key applications include:

-

Power Plants – Boiler feedwater pumps and cooling systems.

-

Oil & Gas – Crude oil transport, refinery pumps, and pipeline systems.

-

Chemical Plants – Handling corrosive or hazardous fluids safely.

-

Paper & Pulp – Circulating water and chemicals.

-

Water Treatment – Ensuring stable pump operation in fluctuating demand.

No matter the industry, ARVs ensure smooth pump operation and protection.

7. Compact and Multi-Functional Design

One of the unique features of ARVs is that they combine multiple functions in a single device:

-

Check valve – Prevents backflow into the pump.

-

Bypass valve – Automatically diverts flow when required.

-

Flow control – Maintains minimum safe flow conditions.

This compact, all-in-one design reduces the need for multiple valves and control systems, making ARVs easy to install and maintain.

8. Enhanced Plant Safety and Reliability

When pumps fail, the entire plant can face safety risks, downtime, and production losses. By keeping pumps running smoothly, ARVs directly improve plant safety and reliability.

This is especially important in industries handling high-pressure, high-temperature, or hazardous fluids where pump failures can be dangerous.

Final Thoughts

Installing Automatic Recirculation Valves (ARVs) in your plant is not just about protecting pumps—it’s about ensuring overall reliability, efficiency, and cost savings.

By automatically maintaining the minimum required flow, an ARV valve:

-

Prevents pump damage.

-

Reduces maintenance costs.

-

Extends equipment life.

-

Ensures safe and stable operations.

-

Delivers long-term savings for the plant.

For industries where pumps are critical to daily operations, ARVs are not optional—they are essential.

If you want to improve pump protection, reduce downtime, and maximize efficiency, consider installing Automatic Recirculation Valves in your system. They are a small investment that delivers huge long-term benefits.