IMARC Group’s report, “Pavers Block Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” offers a complete roadmap for establishing a modern pavers block production unit. The report provides detailed insights into pavers block manufacturing processes, capital investments, operating costs, profitability projections, and financial analysis, enabling entrepreneurs, investors, and construction industry stakeholders to make informed decisions in the growing building materials sector.

In 2025, the demand for pavers block manufacturing plants is increasing across residential, commercial, and infrastructure projects. This project report provides comprehensive cost analysis, machinery requirements, raw material sourcing, and plant layout guidelines for investors across India, the UAE, the US, Africa, and Europe.

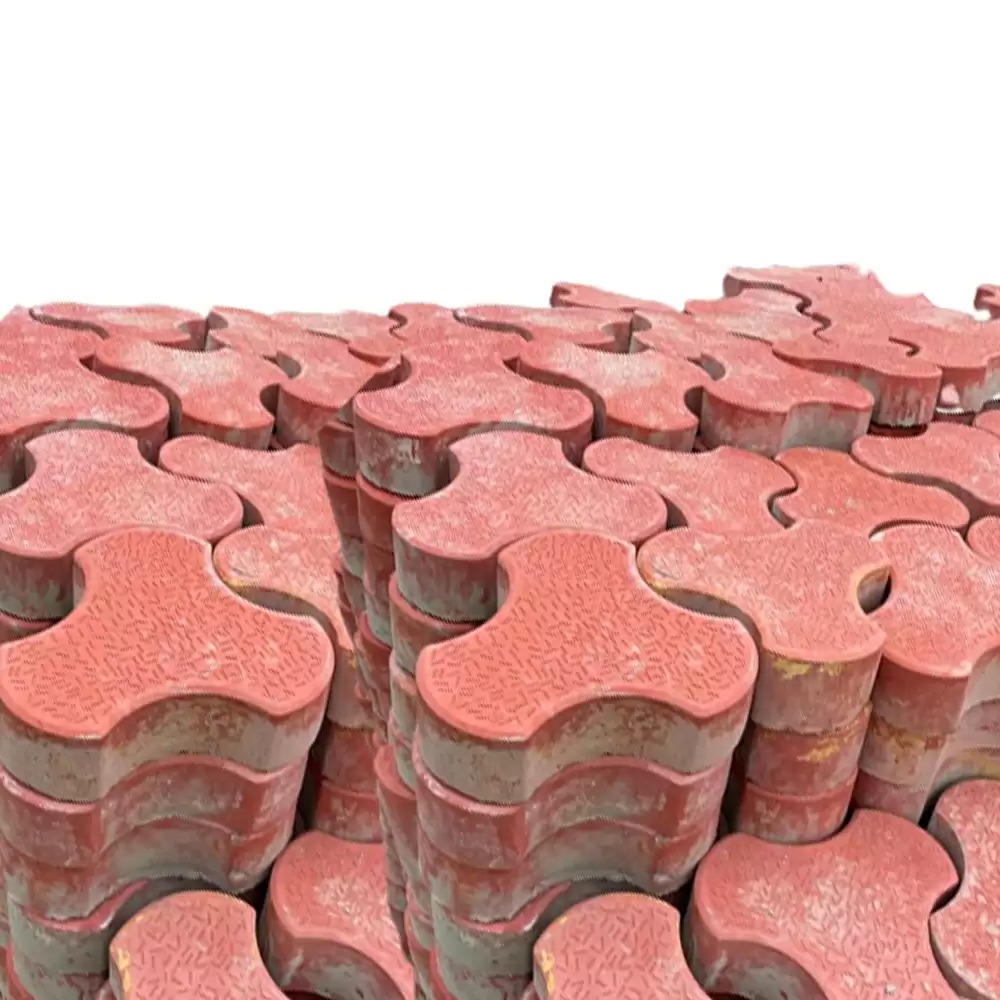

What Are Pavers Blocks?

Pavers blocks are strong, decorative, and durable concrete or cement-based blocks used for outdoor flooring applications such as driveways, parking areas, walkways, landscaping zones, and industrial flooring. Manufactured using cement, aggregates, pigments, and advanced compaction techniques, paver blocks offer exceptional compressive strength, skid resistance, and aesthetic appeal. They come in various shapes, colors, textures, and patterns, making them a preferred choice for modern urban infrastructure. Their easy installation, low maintenance, and long service life continue to fuel global demand.

How Much Does It Cost to Set Up a Pavers Block Manufacturing Plant?

Establishing a pavers block plant involves expenses related to land acquisition, factory construction, machinery (vibrating tables, block-making machines, mixers, molds), utilities, raw materials, labor, curing systems, and packaging. Additional costs include installation, quality testing equipment, storage facilities, transportation, and regulatory approvals. The total investment varies based on production capacity, automation level (manual/semi-automatic/fully automatic), and regional market conditions.

Market Trends and Drivers of Pavers Block Industry:

The pavers block market is witnessing strong growth driven by:

• Rising investments in smart city and urban infrastructure projects

• Rapid expansion of real estate and commercial construction

• Increasing preference for eco-friendly and permeable paving materials

• Demand for aesthetic outdoor landscaping solutions

• Technological advancements in block manufacturing machinery

• Government emphasis on sustainable and modular paving systems

Setup Cost Analysis for a Pavers Block Plant

Setting up a pavers block manufacturing plant involves expenses for land, building construction, machinery (mixers, block-making machines, vibrating tables, molds), raw materials, utilities, labor, and curing systems. Additional costs include power backup, quality testing equipment, packaging, storage, and transportation. The overall investment varies depending on production capacity and automation level—manual plants require lower capital, while fully automatic units demand higher upfront costs but offer greater efficiency and output.

Download the Sample Report: https://www.imarcgroup.com/pavers-block-manufacturing-plant-project-report/requestsample

Key Insights Covered in the Pavers Block Manufacturing Plant Report

Market Coverage:

- Market Trends in construction materials, landscaping, and urban infrastructure

- Market Segmentation by product type, material, application, and design

- Regional Analysis of consumption and production trends

- Price Analysis of cement, aggregates, pigments, molds, and packaging

- Impact of COVID-19 and post-pandemic recovery in construction

- Market Forecast showcasing growth potential through 2030

Key Aspects Required for Setting Up a Pavers Block Manufacturing Plant-

Detailed Process Flow:

- Product Overview

- Unit Operations Involved

- Mass Balance and Raw Material Requirements

- Quality Assurance Criteria

- Technical Tests

Project Details, Requirements, and Costs Involved:

- Land, Location and Site Development

- Plant Layout

- Machinery Requirements and Costs

- Raw Material Requirements and Costs

- Packaging Requirements and Costs

- Transportation Requirements and Costs

- Utility Requirements and Costs

- Human Resource Requirements and Costs

Project Economics:

• Capital Investments: Land acquisition, machinery, utilities, civil work

• Operating Costs: Raw materials, utilities, labor, maintenance

• Expenditure Projections for short-term and long-term planning

• Revenue Projections based on domestic and international demand

• Taxation and Depreciation

• Profit Projections: ROI, NPV, break-even analysis

• Financial Feasibility and risk management

Request a Customized Project Report: https://www.imarcgroup.com/request?type=report&id=11127&flag=C

Customization Options Available:

• Plant Location: Selection of optimal location based on supply chain access and market proximity.

• Plant Capacity: Customization based on targeted production scale.

• Machinery: Options for fully automatic, semi-automatic, or manual production lines.

• List of Machinery Providers: Identification of domestic and international equipment suppliers

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modelling to assess the feasibility and financial viability of establishing new manufacturing plants globally.

Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design’s impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Our expertise includes:

- Market Entry and Expansion Strategy

- Feasibility Studies and Business Planning

- Company Incorporation and Factory Setup Support

- Regulatory and Licensing Navigation

- Competitive Analysis and Benchmarking

- Procurement and Supply Chain Research

- Branding, Marketing, and Sales Strategy

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

Visit homepage: https://kinkedpress.com/