In the world of advanced manufacturing, laser beam welding has emerged as a game-changing solution. When accuracy, speed, and strength matter, nothing outperforms the capabilities of a high-quality laser beam welder. For industries ranging from automotive to aerospace and electronics, laser welding has become the gold standard for joining materials with unmatched finesse. At the forefront of this technology is LaserChina, a trusted name that brings precision-engineered solutions and state-of-the-art laser systems to industries across the globe.

The Rise of Laser Beam Welding

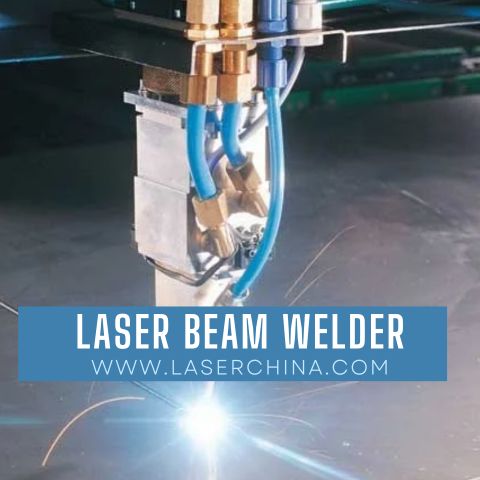

Laser beam welding (LBW) is a non-contact process that uses a focused beam of light to melt and fuse materials, typically metals or thermoplastics. Unlike traditional welding methods that may require filler materials or generate significant heat-affected zones, LBW delivers a highly concentrated heat source, enabling narrow, deep welds with minimal thermal distortion. This technology is ideal for applications where traditional welding might compromise material integrity or visual appearance.

One of the standout benefits of laser welding is its suitability for automation. Robotic laser welding systems can be programmed for intricate patterns, tight tolerances, and repeatable outcomes—making the process perfect for high-volume manufacturing. LaserChina offers a full suite of laser welding equipment built to accommodate everything from small precision components to large industrial parts.

Why LaserChina is the Go-To Provider

What separates LaserChina from other providers is a combination of cutting-edge innovation, reliability, and customization. Their laser beam welders come with options for fiber, CO₂, or hybrid lasers, giving users flexibility based on their specific application and material requirements. Whether you’re welding stainless steel, aluminum, titanium, or exotic alloys, LaserChina machines are engineered to perform with exceptional efficiency.

Moreover, LaserChina offers turnkey solutions, integrating laser sources, welding heads, motion control systems, and cooling systems into a single cohesive package. With a dedicated team of engineers and technicians, they assist customers from product selection to training and after-sales support. That means every client gets a tailored experience, resulting in faster adoption and minimized downtime.

Applications Across Diverse Industries

LaserChina’s laser beam welder are actively used in industries that demand high precision and durability. In the automotive sector, laser welding is used for body panels, battery modules, and transmission components. In medical device manufacturing, it ensures clean, precise welds for surgical instruments and implants. Electronics manufacturers leverage the process to connect delicate components without heat damage, while aerospace engineers depend on laser welding for critical structural parts that must endure extreme conditions.

Each of these industries shares a common need: reliable welds with zero compromise. And that’s exactly what LaserChina delivers through its advanced technology and customer-focused engineering approach.

Final Thought

In today’s manufacturing world, precision isn’t a luxury—it’s a necessity. If your production line demands top-tier welding performance, LaserChina’s laser beam welders offer a reliable, future-ready solution that will redefine how you approach material joining.