Introduction to Precast Concrete Detailing

What is precast concrete detailing?

Precast concrete detailing involves the preparation of shop drawings and specifications for precast concrete components used in construction. It ensures that all elements fit seamlessly into the overall design, improving efficiency and durability.

Importance in modern construction projects

Precast concrete detailing is crucial in streamlining construction projects by reducing material wastage, enhancing structural integrity, and speeding up the building process.

How it enhances efficiency and quality

By using precise detailing, contractors and engineers can minimize errors, ensure proper load distribution, and maintain consistent quality across various components.

Advantages of Precast Concrete in Construction

Durability and strength benefits

Precast concrete offers superior strength and resilience compared to traditional cast-in-place concrete. It is manufactured under controlled conditions, ensuring high durability and reduced susceptibility to environmental damage.

Cost-effectiveness in large projects

The prefabrication of concrete elements reduces labor costs and construction time, making it a cost-effective solution for large-scale infrastructure and building projects.

Environmental benefits of precast concrete

Precast concrete significantly reduces construction waste and allows for better resource utilization. It also supports sustainable building practices by incorporating recyclable materials.

Key Components of Precast Concrete Detailing

Precast concrete panels

These panels are widely used for facades, walls, and floors in both residential and commercial structures. They provide excellent insulation and aesthetic flexibility.

Beams and columns

Structural integrity in precast construction depends on well-designed beams and columns that support load distribution efficiently and ensure stability.

Connection details and joints

Proper detailing of connections and joints is essential for ensuring seamless integration of precast components. This prevents structural failures and enhances longevity.

Understanding Precast Concrete Design & Fabrication

Design considerations

Precast concrete design involves analyzing load requirements, material selection, and adherence to industry standards to ensure the safety and functionality of structures.

Fabrication techniques

Modern fabrication techniques include automated casting, steam curing for strength enhancement, and advanced mold designs that ensure precision and uniformity in components.

Challenges and solutions in detailing

Common challenges in precast detailing include managing weight constraints, transportation logistics, and ensuring precise on-site assembly. Solutions include modular designs and the use of high-performance materials.

Software & Tools for Precast Concrete Detailing

AutoCAD and Revit in detailing

AutoCAD and Revit are essential software tools for creating detailed 2D and 3D models, ensuring precise planning and execution of precast components.

Tekla Structures for 3D modeling

Tekla Structures is widely used for generating highly accurate 3D models, enabling better visualization, clash detection, and coordination with other construction disciplines.

BIM (Building Information Modeling) applications

BIM enhances collaboration among stakeholders, streamlining the design and construction process by integrating detailed data for efficient project management.

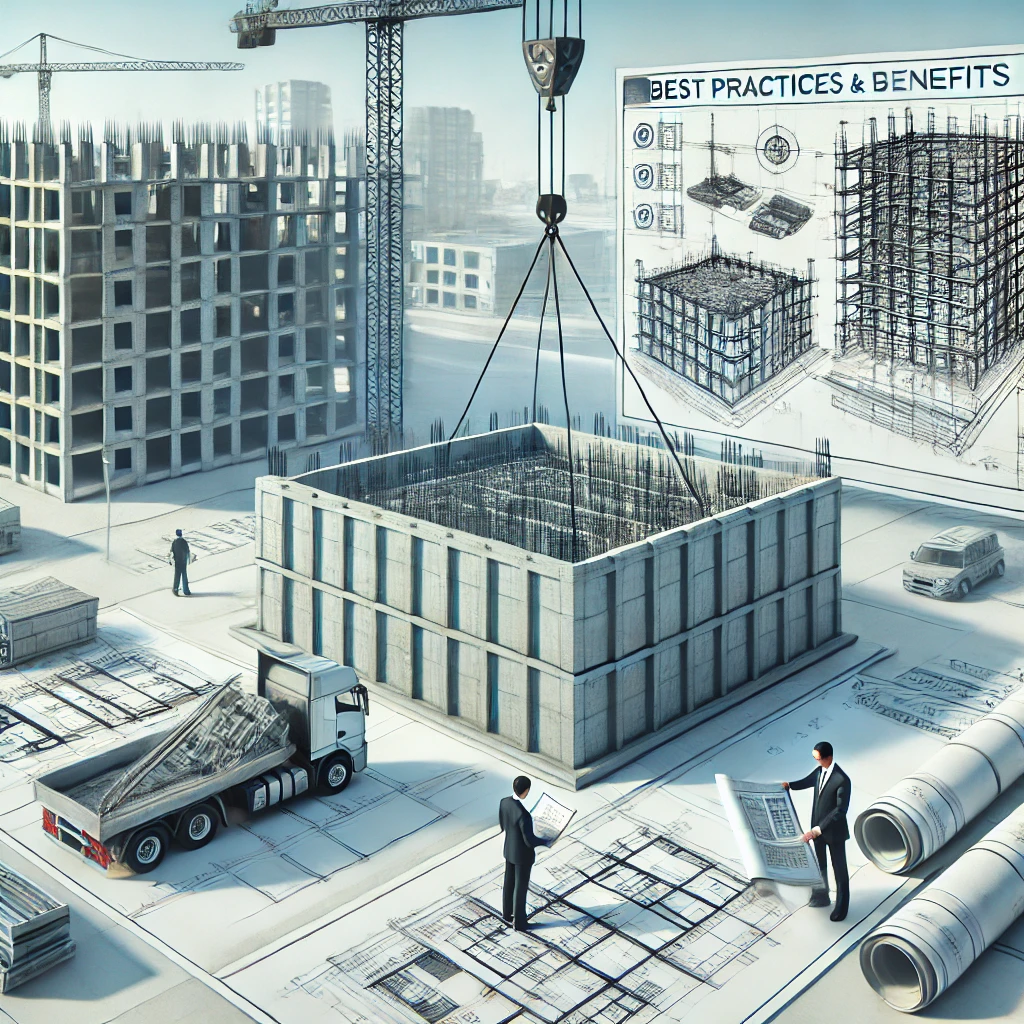

Best Practices for Precast Concrete Detailing

Ensuring accuracy in drawings

Accurate shop drawings help avoid costly errors during fabrication and installation, ensuring smooth execution on-site.

Managing tolerances and dimensions

Proper tolerances must be maintained to allow seamless assembly, preventing structural misalignment and inconsistencies.

Coordination with architects and engineers

Effective communication with project stakeholders is essential to align design expectations and ensure constructability.

Common Challenges and How to Overcome Them

Handling structural load requirements

Structural integrity relies on detailed calculations and testing to ensure the load-bearing capacity of precast elements.

Waterproofing and joint detailing

Specialized sealants and connection designs prevent water infiltration, improving the longevity of precast structures.

Transportation and installation challenges

Precast elements must be transported with care, and installation should follow precise sequencing to maintain stability and alignment.

Industry Standards & Codes for Precast Concrete Detailing

ACI (American Concrete Institute) standards

The ACI provides guidelines and best practices for the detailing, manufacturing, and installation of precast concrete elements, ensuring safety and compliance.

PCI (Precast/Prestressed Concrete Institute) guidelines

PCI sets industry benchmarks for quality control, performance, and sustainability in precast concrete detailing and construction.

Local and international building codes

Adhering to regional building codes ensures structural integrity and compliance with legal construction standards.

Applications of Precast Concrete in Various Sectors

Residential buildings

Precast elements are commonly used in residential projects to provide durable walls, floors, and roofs with minimal construction time.

Commercial and industrial projects

Precast concrete enhances large-scale structures, such as office buildings, warehouses, and factories, by offering speed and efficiency.

Infrastructure (bridges, tunnels, highways)

Precast concrete plays a critical role in transportation infrastructure, improving the durability and longevity of roads, bridges, and tunnels.

The Role of Precast Concrete in Sustainable Construction

Reduction in material waste

Precast construction minimizes onsite material waste, making it a more sustainable choice compared to traditional concrete casting methods.

Energy efficiency in manufacturing

Precast concrete components are produced in controlled environments, optimizing energy use and reducing emissions.

Long lifespan and recyclability

Precast structures offer extended durability and can be recycled at the end of their life cycle, reducing environmental impact.

Conclusion

Precast concrete detailing is a crucial aspect of modern construction, offering numerous benefits, including durability, efficiency, and cost-effectiveness. With proper planning, adherence to industry standards, and the use of advanced software tools, precast concrete can significantly enhance the quality and longevity of structures. As the industry continues to evolve, embracing sustainable practices and innovative technologies will further solidify precast concrete’s role in the future of construction.

Frequently Asked Questions (FAQs)

1. What are the key benefits of precast concrete?

Precast concrete offers superior strength, faster construction time, reduced material waste, and cost efficiency compared to traditional construction methods.

2. How does precast concrete detailing improve project efficiency?

Detailed precast drawings ensure precise component fabrication, reducing errors, saving time, and minimizing rework on-site.

3. What software is used for precast concrete detailing?

Popular software tools include AutoCAD, Revit, Tekla Structures, and BIM applications for 3D modeling and project collaboration.

4. What are the challenges in precast concrete installation?

Challenges include handling structural loads, ensuring waterproofing, and managing transportation logistics to maintain quality and alignment.

5. Is precast concrete environmentally friendly?

Yes, precast concrete reduces waste, enhances energy efficiency, and allows for recyclability, making it a sustainable choice for modern construction.

Learn about The Importance of High-Quality Steel and Concrete Solutions in Dubai’s Construction Industry