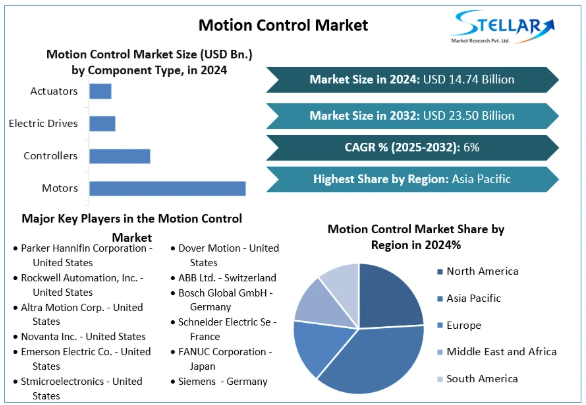

Motion Control Market size was valued at USD 14.74 Bn. in 2024 and the total Global Motion Control Market size is expected to grow at a CAGR of 6% from 2025 to 2032, reaching nearly USD 23.50 Bn. by 2032.

Market Estimation & Definition

The Motion Control Market refers to the integrated systems and technologies that regulate and manage movement in machinery and industrial processes. These systems include motors, drives, controllers, actuators, sensors, and software that work together to control the speed, position, and torque of mechanical components.

As of 2024, the market stands at USD 14.74 billion, fueled by the increasing need for automation in manufacturing, robotics, and logistics. By 2032, the market is expected to reach USD 23.50 billion, reflecting the growing reliance on motion technologies to enhance operational efficiency, precision, and scalability.

Market Growth Drivers & Opportunities

Key Growth Drivers

-

Industry 4.0 & Smart Manufacturing: The rise of smart factories, digital twins, and cyber-physical systems is driving the integration of motion control systems with IoT, AI, and machine learning. This enables real-time feedback, autonomous operations, and predictive maintenance capabilities.

-

Expansion of the Robotics Industry: Motion control is essential in robotic arms, autonomous vehicles, and collaborative robots (cobots), which are now widely adopted in automotive, electronics, and healthcare sectors.

-

Semiconductor and Electronics Demand: Ultra-high precision motion control systems are in demand for semiconductor wafer handling, photolithography, and micro-assembly, all requiring sub-micron-level accuracy.

-

Rising Use in Packaging and FMCG: High-speed packaging, labeling, and filling machines depend on precise motion systems to maintain efficiency, reduce waste, and ensure consistent output.

Emerging Opportunities

-

Decentralized Motion Architecture: Advances in modular systems and edge computing are enabling decentralized control, improving system flexibility and reducing installation complexity.

-

Sustainable and Energy-Efficient Systems: Increasing emphasis on carbon-neutral operations is pushing companies to invest in energy-efficient servo drives and regenerative braking systems.

-

Asia-Pacific Industrial Expansion: With the rapid industrialization of China, India, and Southeast Asia, the demand for motion control systems is soaring across manufacturing, logistics, and renewable energy sectors.

-

Medical Device Manufacturing: Precision motion control systems are critical in diagnostics, laboratory automation, and drug delivery systems, opening opportunities in the life sciences industry.

Segmentation Analysis

The Motion Control Market is segmented by component, system type, application, and region:

By Component

-

Motors

-

Drives

-

Controllers

-

Actuators

-

Sensors

-

Software & Services

Motors and drives hold a significant share due to their core role in mechanical movement. Controllers and feedback systems are gaining traction as smart, AI-enabled solutions enter the market.

By System Type

-

Open-Loop Systems

-

Closed-Loop Systems

Closed-loop systems dominate the market due to their superior accuracy and reliability in industrial applications. They are preferred in scenarios where feedback is critical, such as CNC machines and robotics.

By Application

-

Automotive

-

Semiconductors & Electronics

-

Food & Beverage

-

Pharmaceuticals

-

Aerospace & Defense

-

Packaging

-

Industrial Machinery

-

Others (e.g., Logistics, Energy)

The automotive sector continues to be the largest consumer of motion control technologies, especially for production line automation. Semiconductors and electronics follow closely, while the fastest-growing segment is anticipated to be pharmaceuticals and packaging, due to rising global demand for high-precision, automated solutions.

By Region

-

North America

-

Europe

-

Asia-Pacific

-

Latin America

-

Middle East & Africa

Asia-Pacific holds the largest market share, driven by significant investments in industrial automation across China, Japan, and India. North America and Europe follow, with strong adoption in aerospace, automotive, and smart manufacturing.

Country-Level Analysis: United States & Germany

United States

The U.S. represents one of the most technologically advanced markets for motion control systems. With a well-established industrial base, particularly in automotive, aerospace, and electronics, the U.S. leads in adopting high-end servo systems, AI-integrated controllers, and IoT-enabled monitoring.

U.S.-based manufacturers are also pioneers in edge-based control systems, helping factories streamline operations with reduced latency and increased data accuracy. Government incentives for smart factory development further boost the demand for motion solutions.

Germany

Germany stands as Europe’s automation and precision engineering leader. Known for its advanced machinery and automotive sectors, the country shows strong adoption of closed-loop systems, high-speed linear motors, and integrated feedback solutions.

German industries emphasize compliance with energy efficiency standards and modular system architectures. The growing focus on sustainability and digital manufacturing ensures consistent investment in motion control solutions, making Germany a strategic hub for both production and R&D.

Commutator (Consumer Usage) Analysis

In this context, “commutator” analysis is interpreted as the patterns of usage across various consumer industries—specifically those with high-frequency, high-reliability operational needs.

High-Usage Applications (Continuous Operation)

-

Automotive Assembly Lines: Robotic welding, painting, and part alignment all depend on reliable motion control for uptime and safety.

-

Pharmaceutical Production: Dosing, filling, and packaging systems operate in cleanrooms with strict hygiene and precision requirements.

-

Warehousing and Logistics: Automated guided vehicles (AGVs), sortation systems, and conveyors run around the clock, demanding rugged, responsive motion systems.

-

Semiconductor Fabrication: Every wafer process—etching, lithography, inspection—relies on high-speed, nanometer-level motion accuracy.

-

Food and Beverage Packaging: Rapid processing lines for bottling, capping, and labeling rely on consistent, repeatable motion sequences.

These segments represent the “commuter class” of motion system users—industries where motion control is central to operational continuity, product quality, and throughput efficiency.

Conclusion

The Motion Control Market is entering a high-growth era, fueled by the convergence of automation, digital intelligence, and precision manufacturing. With the global market forecasted to rise from USD 14.74 billion in 2024 to USD 23.50 billion by 2032, players across the value chain must innovate to meet the increasing complexity and expectations of modern industry.

From robotic assembly and semiconductor precision to pharma automation and smart packaging, motion control technologies are redefining how industries operate. The shift to closed-loop systems, AI-enabled feedback, and decentralized architectures positions motion control as the backbone of next-generation manufacturing.

Opportunities are especially strong in the Asia-Pacific region, where industrial growth and automation investment remain unmatched. Meanwhile, countries like the United States and Germany continue to lead innovation and global standards in motion technology.

About Stellar Market Research:

Stellar Market Research is a multifaceted market research and consulting company with professionals from several industries. Some of the industries we cover include science and engineering, electronic components, industrial equipment, technology, and communication, cars, and automobiles, chemical products and substances, general merchandise, beverages, personal care, and automated systems. To mention a few, we provide market-verified industry estimations, technical trend analysis, crucial market research, strategic advice, competition analysis, production and demand analysis, and client impact studies.

Contact Stellar Market Research:

S.no.8, h.no. 4-8 Pl.7/4, Kothrud,

Pinnac Memories Fl. No. 3, Kothrud, Pune,

Pune, Maharashtra, 411029

+91 20 6630 3320, +91 9607365656