Masterbatch Manufacturers: A Complete Industry Overview by Opulence Chicago LLC

Masterbatch Manufacturers play a critical role in modern industrial production, supplying essential materials that improve the color, performance, and durability of plastics. As industries continue to evolve and demand higher-quality products, the importance of reliable masterbatch solutions becomes even greater. Opulence Chicago LLC understands this growing need, offering a detailed look into how masterbatch manufacturing shapes the global plastics sector.

Whether used in packaging, automotive components, medical supplies, consumer products, or construction materials, masterbatch formulations help companies achieve consistent results and long-term product performance. This guide explores how the manufacturing process works, the different types of masterbatch available, and why trusted manufacturers remain essential in today’s competitive market.

What Masterbatch Manufacturers Do

Masterbatch Manufacturers produce concentrated mixtures of pigments, additives, and polymer carriers. These mixtures are added to natural polymers during the manufacturing process to achieve specific colors or performance characteristics.

The purpose of masterbatch is simple. It allows manufacturers to enhance plastics without altering the base polymer directly. This creates stable, customizable, and efficient production outcomes. Opulence Chicago LLC recognizes the value of reliable masterbatch solutions for operations that require consistency and precise material properties.

Importance of Masterbatch in Modern Industries

Plastics are used everywhere, and nearly every plastic product relies on some form of masterbatch. From vibrant packaging films to UV-resistant outdoor furniture, the impact of masterbatch technology is widespread.

Industries depend on masterbatch for:

• Color consistency

• Improved durability

• Enhanced strength

• UV protection

• Antimicrobial properties

• Fire resistance

• Smooth processing

Because plastics must meet strict performance standards, Masterbatch Manufacturers ensure that each formulation delivers reliability and long-lasting results.

Types of Masterbatch Used Across Industries

Different applications require different masterbatch solutions. Understanding the major categories helps businesses choose the right material for their production needs.

Color Masterbatch

Color masterbatch is used to achieve consistent and vibrant color in plastic products. Manufacturers tailor the formulation to match precise color codes, ensuring accurate results in every production batch.

Color masterbatch is essential for:

• Packaging

• Household goods

• Toys

• Consumer electronics

• Automotive interiors

Opulence Chicago LLC highlights the importance of accurate color matching because branding and product appeal rely heavily on visual consistency.

Additive Masterbatch

Additive masterbatch enhances the functional performance of plastics. These additives provide special characteristics that improve usability and durability.

Common types include:

• UV stabilizers

• Antimicrobial additives

• Anti-static agents

• Flame retardants

• Slip agents

• Anti-fog agents

Manufacturers use additive masterbatch to ensure their products meet safety, regulatory, and environmental standards.

Filler Masterbatch

Filler masterbatch is used to reduce production costs while enhancing material strength. It includes fillers like calcium carbonate that help improve stiffness, thermal resistance, and processing efficiency.

This type of masterbatch is widely used in:

• Packaging films

• Injection-molded items

• Pipes

• Household goods

Filler masterbatch improves performance while lowering raw material expenses.

Polymer-Specific Masterbatch

Some masterbatch types are designed for specific polymers such as PET, PP, PE, PVC, and ABS. These formulations help ensure compatibility between the masterbatch and the base polymer.

Opulence Chicago LLC acknowledges that compatibility is crucial, especially when manufacturing high-performance products.

The Masterbatch Manufacturing Process

Masterbatch Manufacturers follow a detailed process to create consistent, high-quality materials. Every step requires precision to ensure that the final product meets industry standards.

Step 1: Raw Material Selection

High-quality pigments, additives, and polymer carriers are chosen. The purity of these materials influences the strength, color, and performance of the final masterbatch.

Step 2: Mixing and Compounding

The raw materials are blended in precise proportions. Advanced compounding machines mix and melt the ingredients to form a uniform mixture.

Step 3: Extrusion

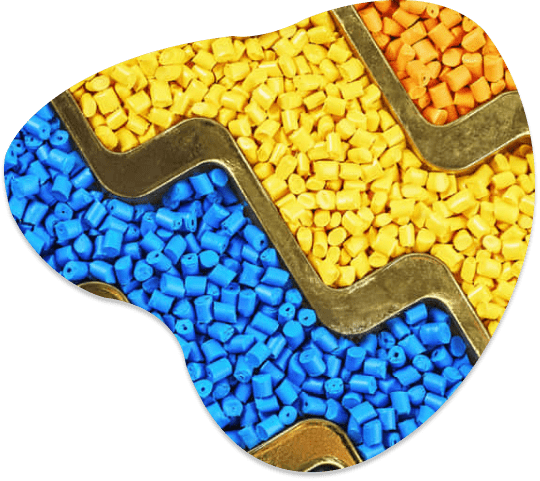

The mixture is melted and processed through an extruder. The molten material forms long strands, which are cooled and prepared for the next stage.

Step 4: Pelletizing

The strands are cut into small pellets. These pellets are the final masterbatch product that manufacturers use in their plastic production processes.

Step 5: Quality Testing

Every batch undergoes strict quality testing to ensure:

• Color accuracy

• Performance consistency

• Compatibility with polymers

• Heat stability

• Dispersion quality

Opulence Chicago LLC emphasizes that continuous quality control helps manufacturers deliver reliable results across different industries.

Why Businesses Need Reliable Masterbatch Manufacturers

In industrial production, consistency is everything. Even minor variations can affect product quality, performance, or compliance. This is why choosing a dependable manufacturer matters.

Reliable Masterbatch Manufacturers offer:

• Custom formulations

• Stable color consistency

• High-performance additives

• Support for large-scale production

• Knowledge of industry standards

• Sustainable materials and solutions

With industries becoming more competitive, companies depend on manufacturers that can deliver both quality and scalability.

Applications of Masterbatch Across Industries

Masterbatch technology supports countless industries. It ensures that plastic products remain strong, attractive, and safe for use.

Key industrial applications include:

• Packaging materials

• Automotive parts

• Electrical and electronic goods

• Medical devices

• Construction products

• Cable insulation

• Consumer goods

Because each sector has unique needs, Masterbatch Manufacturers develop customized solutions that align with specific performance requirements.

How Masterbatch Supports Sustainability

Sustainability is becoming a top priority in plastic production. Masterbatch plays an important role in helping industries reduce waste and improve product lifespan.

Sustainable benefits include:

• Lower pigment waste

• Efficient material usage

• Enhanced durability to reduce replacements

• Support for recycled materials

• Reduced energy consumption in processing

Opulence Chicago LLC recognizes that environmentally friendly solutions are essential for the future of manufacturing.

Choosing the Right Masterbatch Partner

Selecting Masterbatch Manufacturers is an important decision for any company that relies on plastic production. Businesses should look for partners who offer:

• High-quality raw materials

• Advanced technology

• Custom color matching

• Technical support

• Reliable delivery

• Strong quality testing procedures

These qualities ensure long-term consistency and performance for all plastic products.

Conclusion

Masterbatch Manufacturers play a vital role in supporting industries that depend on high-quality plastics. With their ability to enhance color, durability, and performance, masterbatch solutions ensure that products meet modern standards of reliability and appeal. Opulence Chicago LLC recognizes the significance of selecting trusted manufacturers who can deliver consistent results across various industrial applications.

As industries continue to evolve, masterbatch will remain essential for producing strong, vibrant, and long-lasting plastic materials. Choosing the right manufacturer ensures quality, efficiency, and success in every production line.