Construction is no longer what it used to be. With technology taking over every part of life, even building projects are seeing big improvements. One of the biggest changes in recent years is the use of machines to make construction faster, cheaper, and cleaner. One such machine making a strong impact is the interlocking block making machine.

Whether you’re building a home, school, wall, or commercial structure, this machine can save you time, labour, and money. In this guide, you’ll learn how it works and why it’s becoming essential for modern construction.

What is an Interlocking Block Making Machine?

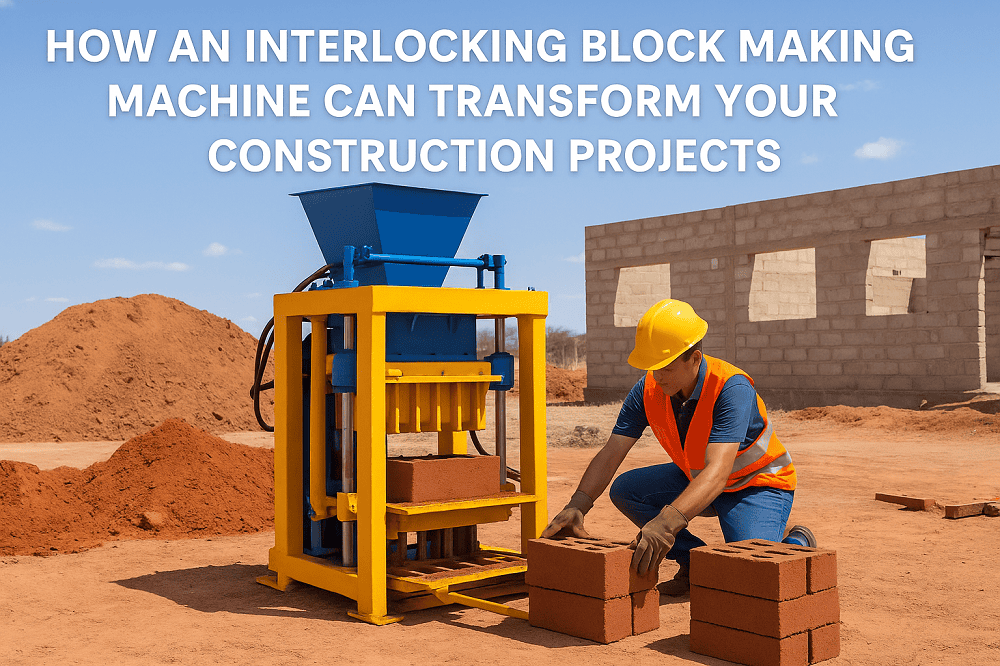

An interlocking block making machine is a machine that creates specially shaped blocks. These blocks have ridges and grooves on the sides. When stacked, they fit into each other like puzzle pieces. Because of this, there’s no need for cement or mortar between the blocks.

This design makes the building process much quicker. These machines can produce blocks using a mix of soil, sand, cement, and water. Some models also support fly ash and other waste materials.

Interlocking blocks are strong, durable, and versatile. That’s why they’re becoming popular in many parts of the world, especially in low-cost housing projects.

Why Interlocking Blocks Are Better

Here are some key reasons why interlocking blocks and the machines that produce them are gaining attention:

- No mortar required – No need to buy and apply cement between blocks.

- Faster construction – Blocks are easy to place and align.

- Lower costs – Less labour, less material, more savings.

- Eco-friendly – Uses less cement, sometimes recycled materials.

- Reusability – Blocks can be reused in temporary structures.

- Uniform size and shape – Makes the walls neat and stable.

Interlocking blocks are ideal for homes, schools, walls, pavements, and even disaster-relief structures.

How the Machine Works

The interlocking block making machine works in a simple and efficient way:

- Raw Material Input – Add the mix of soil, cement, sand, and water into the hopper.

- Mixing Process – Some machines have built-in mixers to blend the materials.

- Compression Stage – The mixture is pressed into moulds using hydraulic or mechanical force.

- Block Ejection – The newly formed blocks are pushed out of the mould.

- Curing – Blocks are air-dried or water-cured for a few days to gain strength.

The machine ensures each block is consistent in size and shape. This improves the quality of the structure being built.

Types of Interlocking Block Making Machines

There are three main types of machines available:

1. Manual Machine

- Cheapest option.

- Ideal for small-scale or rural projects.

- Needs more manpower.

- Good for areas with no electricity.

2. Semi-Automatic Machine

- Mid-range cost.

- Some operations are electric; others are manual.

- Suitable for medium-sized projects.

- Faster and more efficient than manual.

3. Fully Automatic Machine

- Highest production capacity.

- High upfront investment.

- Runs on electricity, needs less labour.

- Best for large-scale commercial use.

Your choice depends on your budget, location, and daily production needs.

Key Benefits for Construction Projects

Let’s break down the major benefits this machine offers:

a. Saves Construction Time

Laying interlocking blocks takes less time than traditional bricks. With consistent shapes, builders can complete work faster.

b. Reduces Labour Needs

Blocks are easy to align and stack. Fewer workers are needed on-site. You also save time spent mixing and applying mortar.

c. Keeps the Worksite Clean

With no mortar, there’s less spillage. This keeps the site cleaner and safer for workers.

d. Reduces Building Costs

The machine reduces costs by lowering the need for cement and skilled labour. You get more value with every project.

e. Improves Building Strength

Blocks are compressed under pressure, making them dense and strong. This adds to the safety and durability of the building.

f. Customizable Designs

You can use different moulds to produce blocks in various shapes and sizes depending on your project needs.

Use Cases and Applications

Interlocking blocks are used in many construction scenarios. Some common applications include:

- Affordable housing projects

- Compound or boundary walls

- Footpaths and pavements

- Garden and park walls

- Retaining walls in landscaping

- Temporary shelters and classrooms

These blocks are also ideal in remote areas where transporting cement or bricks is hard.

Eco-Friendly and Sustainable Construction

Sustainability is now a top priority in construction. Interlocking blocks help in many ways:

- Use less cement, reducing carbon emissions.

- Often made with local or recycled materials.

- Less water needed for mortar.

- Blocks can be reused or relocated.

Builders who want to go green should seriously consider using this technology.

Things to Check Before Buying

Before buying a machine, consider these points:

- Production Capacity – How many blocks per day?

- Raw Material Compatibility – Can it use local soil or fly ash?

- Machine Durability – Is it made from strong steel?

- Ease of Use – Is it simple to operate?

- Maintenance Needs – Are parts easy to replace?

- After-Sales Service – Does the seller offer support or training?

- Warranty and Reviews – Trusted brand or supplier?

Test the machine or ask for a demo before finalizing.

Real-World Impact

Many small businesses and NGOs have used interlocking block machines to build hundreds of homes in developing regions. For example, in parts of Africa and Asia, these machines are helping solve housing shortages quickly and affordably.

One machine, in many cases, can support an entire community.

Conclusion

The interlocking block making machine is truly a game-changer in construction. It can help you cut costs, speed up work, and deliver better quality results. Whether you’re a small builder, contractor, or social housing provider, this tool offers excellent value.

Make the right investment today and take your construction projects to the next level.