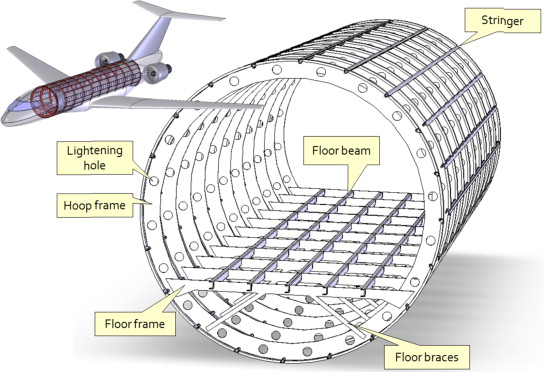

CNC machining has revolutionized aerospace manufacturing by providing high-precision, consistent, and efficient production of complex aircraft components. This technology uses computer-controlled machines to cut, shape, and finish metals such as aluminum, titanium, and high-strength steel with tolerances measured in microns. Precision is critical in aerospace because even minor deviations can compromise structural integrity, safety, and performance. Components like the fuselage structure are central to the Aircraft fuselage framework, forming the backbone that supports Airframe structural components and distributes loads across the Aircraft load-bearing structure. CNC machining allows manufacturers to maintain exacting standards while optimizing production efficiency, ensuring that each Fuselage frame assembly meets rigorous engineering and regulatory requirements.

Understanding Modern CNC Machining

How the CNC Process Works

CNC machining starts with a detailed digital design in CAD software, where engineers define the geometry, dimensions, tolerances, and functional requirements. The CAD model is then converted into CAM instructions that guide the machine’s tool paths, spindle speed, and cutting strategy. The CNC machine executes these instructions with minimal manual intervention, ensuring repeatability and high precision across multiple components. In aerospace, this process is crucial for creating the fuselage structure as it ensures that all parts of the Aircraft fuselage framework and Airframe structural components fit together perfectly, minimizing assembly stress and improving structural reliability throughout the aircraft.

Machine Types and Capabilities

CNC machines come in a variety of configurations to handle different complexity levels. Three-axis machines are suitable for simple geometries, while four-axis machines provide rotational movement to access complex surfaces. Five-axis CNC systems enable simultaneous multi-directional cutting, which reduces setups and ensures precise fabrication of intricate Fuselage frame assembly components. CNC turning centers are used for cylindrical parts requiring precise concentricity. Advanced tooling, high-speed spindles, and precise control enable manufacturers to maintain tight tolerances and achieve superior surface finishes, which are critical for elements of the Aircraft load-bearing structure exposed to extreme stress and operational loads.

Why Precision and Tolerance Matter

Dimensional Accuracy and Repeatability

Precision and repeatability are essential in aerospace CNC machining. Dimensional accuracy ensures that each component conforms to the original design, while repeatability guarantees that every part in a production batch is consistent. For the Aircraft fuselage framework and Airframe structural components, small deviations can affect alignment, load distribution, and structural integrity. Engineers account for material properties, thermal expansion, and machining stress to maintain strict tolerances. This control ensures that each component of the Fuselage frame assembly integrates seamlessly, supporting the structural durability and long-term safety of the aircraft.

Cost, Lead Times, and Quality Factors

Tighter tolerances increase production costs and lead times due to specialized tooling, slower machining speeds, and rigorous inspection protocols. However, precise manufacturing reduces the risk of rework, assembly delays, and long-term maintenance issues, making it cost-effective over the life of the aircraft. A balanced tolerance strategy allows manufacturers to maintain efficiency while meeting quality standards. Investing in precision for critical components, such as the Aircraft load-bearing structure and Fuselage frame assembly, improves durability, reduces operational risk, and enhances overall aircraft performance.

CNC Machining in Aerospace Structural Applications

Key Industry Applications

CNC machining is indispensable for producing aerospace structural components that must withstand high loads, vibration, and environmental stress. Common applications include:

-

Structural frames and ribs forming the Aircraft fuselage framework

-

Brackets, mounts, and reinforcements within Airframe structural components

-

Load-bearing elements critical to the Aircraft load-bearing structure

-

Fuselage frame assembly components designed to optimize alignment and weight distribution

These components are typically manufactured from high-strength alloys to meet safety and regulatory standards while maintaining durability under demanding operational conditions. CNC technology ensures that these parts achieve precise tolerances and consistent quality across production batches.

Role in Fuselage Frame Assembly

Fuselage frame assembly requires exact alignment of multiple machined parts to achieve structural integrity and maintain aerodynamic efficiency. CNC machining ensures consistent hole placement, surface flatness, and edge quality, which are critical for riveted or bonded assemblies. By producing high-precision components, CNC technology minimizes assembly stress and ensures proper load transfer across the Aircraft fuselage framework and Airframe structural components. This precision improves long-term durability, reduces maintenance needs, and enhances operational safety, demonstrating the critical role of CNC machining in modern aerospace manufacturing.

Selecting a CNC Manufacturing Partner

Technical Capabilities and Materials

Selecting the right CNC partner is vital for aerospace projects. Key considerations include:

-

Multi-axis machining capabilities to produce complex geometries

-

Experience with advanced alloys such as aluminum, titanium, and high-strength steel

-

Proven expertise in Fuselage frame assembly, Aircraft fuselage framework, and Airframe structural components

-

Detailed process documentation and inspection capabilities

A skilled CNC partner ensures that all parts meet design specifications while maintaining production efficiency, contributing to the structural integrity and compliance of Aircraft load-bearing structure components.

Inspection, Quality, and Communication

Quality assurance is paramount in aerospace CNC machining. Reputable suppliers implement rigorous inspection procedures including coordinate measuring machines, in-process verification, and non-destructive testing where required. Effective communication between design, production, and inspection teams ensures specifications are consistently met. Factors to evaluate a CNC partner include:

-

Strict adherence to inspection procedures and verification protocols

-

Transparent reporting of deviations and corrective actions

-

Consistent delivery aligned with production schedules

Through meticulous inspection, quality management, and clear communication, CNC partners ensure that Fuselage frame assembly, Aircraft fuselage framework, and Airframe structural components meet or exceed aerospace industry standards.

Conclusion

CNC machining is essential in aerospace manufacturing, enabling the production of high-precision, reliable structural components. Advanced digital workflows, multi-axis machining, and strict quality control allow engineers to fabricate Airframe structural components, Aircraft load-bearing structures, and Fuselage frame assembly elements that meet demanding safety and performance standards. Precision, repeatability, and collaboration with a skilled CNC partner are critical to maintaining structural integrity throughout the aircraft lifecycle. CNC machining remains an indispensable technology for producing reliable, high-performance components that uphold the safety, efficiency, and durability of modern aerospace structures.