This question can be answered when we compare the properties of ADI and Steel w.r.t Manufacturing ease, cost competitiveness, machining ease and energy consumption. Some of the parameters in which ADI Castings score higher than Steel are mentioned below:

- Steel is far more difficult to cast than ADI.

- ADI has less stringent draft requirements than steel forgings.

- At temperatures below zero, ADI maintains more of its toughness than steel.

- Stress makes ADI work harder. ADI has more dampening capacity than steel.

- Due to ADI’s lower casting temperature than steel, it is possible to cast complex shapes with sectional changes and achieve a superior surface finish.

The Advantages in terms of Cost

Although the cost of ADI material is less expensive per kilogram than that of steel or aluminum, this only represents a small portion of the potential cost savings because an ADI-designed component can result in cost reductions at every stage of production. The cost to create ADI counterparts can then be half as much as that of an aluminum item or less than that of a steel forging. Value engineering benefits from ADI in number of ways:

- Excellent castability: Ductile iron has a very high yield rate, or the ratio of metal poured to metal supplied, and is easily cast into complex shapes.

- Lower machining costs: ADI is well suited to casting in close to net shape because it requires less metal to be removed from the starting material. Ductile iron has better machinability than free-machining steels before austempering. The cost per kilo is further decreased by the dense, manageable chips that ductile iron and ADI both create.

- Savings on heat treatment: Austempering delivers a higher level of homogeneity and predictable dimensional changes than carburising or induction hardening while generally costing less.

- Low energy content: ADI castings typically require 80% less energy to produce than steel forgings and 50% less energy than steel castings to create.

- Best price: ADI is typically the best deal when considering relative cost per unit of yield strength.

Beyond the direct manufacturing and machining benefits, ADI’s cost advantages multiply when evaluating the entire lifecycle of a component. Because ADI parts offer higher strength-to-weight ratios and superior durability, they often last significantly longer than steel or aluminum alternatives. This extended lifespan reduces the frequency of replacements, minimizing downtime and maintenance expenses in industrial environments. In applications where equipment runs continuously such as mining, construction, heavy vehicles, and agricultural machinery the reduction in wear-related failures alone contributes to substantial yearly savings.

Additionally, the design flexibility of ADI unlocks further cost reductions. Engineers can optimize wall thickness, remove unnecessary mass, and integrate multiple features into a single casting. This consolidation eliminates the need for welded assemblies or multi-piece constructions, which are typically more expensive due to increased labor, alignment, and inspection requirements. ADI’s near-net-shape capability also cuts down on material wastage, making it an economical choice for large or complex components.

Another major cost factor is sustainability. As industries move toward greener operations, ADI’s lower melting and processing temperatures mean reduced carbon emissions during production. Manufacturers prioritizing environmentally responsible sourcing increasingly prefer ADI components because they help achieve sustainability goals while still delivering performance and cost-efficiency. When viewed from a broader operational perspective material cost, machining, energy consumption, lifecycle durability, and design optimization ADI consistently provides a clearer economic advantage over steel castings.

Advantages in terms of performance

Due to their better performance, ADI castings are swiftly supplanting steel forgings, welded fabrications, carburized steel, and aluminum in important applications.

- Steel-equivalent strength

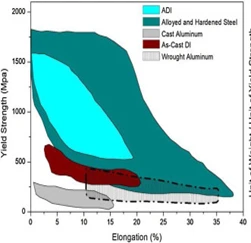

Due to ductile iron’s equal strength, almost 80% of all cast and forged steels may be swapped out for a different grade of ADI. - Less dense than steel

ADI’s relative weight per unit of strength allows for cost-effective design without sacrificing performance. An ADI component will weigh 10% less than steel for a particular shape. - ‘Lighter’ than aluminum

ADI weighs only 2.5 times as much and is three times stronger than the best cast or forged aluminum. A correctly constructed ADI part can replace aluminum while saving weight because it is twice as rigid. - Excellent fatigue strength ADI’s dynamic characteristics are superior to those of forged, cast, and micro-alloyed steels, giving it excellent fatigue strength. In contrast to aluminum, ADI’s endurance limit is steady after tens of millions of cycles.

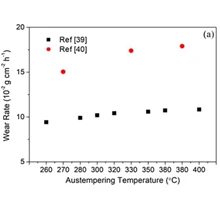

Superior wear and abrasion resistance

At lower “bulk” hardness levels, ADI exhibits greater abrasion resistance than commonly treated steels and irons. ADI improves with service, in contrast to carburized steel, which loses wear resistance as the carburized coating is gone. Its greater wear resistance versus steel at any given hardness level makes it the best material for applications requiring intense abrasion, such as earth moving.

Conclusion

In conclusion, ADI clearly offers superior cost efficiency, durability, and design flexibility compared to traditional steel castings. With these advantages, industries are rapidly shifting toward ADI solutions. JS Auto Cast continues to lead this transition by delivering high-quality ADI components that ensure performance, reliability, and long-term value.