The global bleached kraft pulp market size is projected to grow at a CAGR of 5% over the forecast period of 2025-2034. As industries continue to focus on sustainability and environmental responsibility, bleached kraft pulp is gaining traction due to its eco-friendly and versatile nature. Used primarily in the production of high-quality paper products, bleached kraft pulp plays a critical role in meeting the growing demand for packaging, tissue, and graphic paper. This blog post explores the dynamics of the global bleached kraft pulp market, including its market segmentation, key drivers, regional insights, competitive landscape, and future outlook.

Market Overview

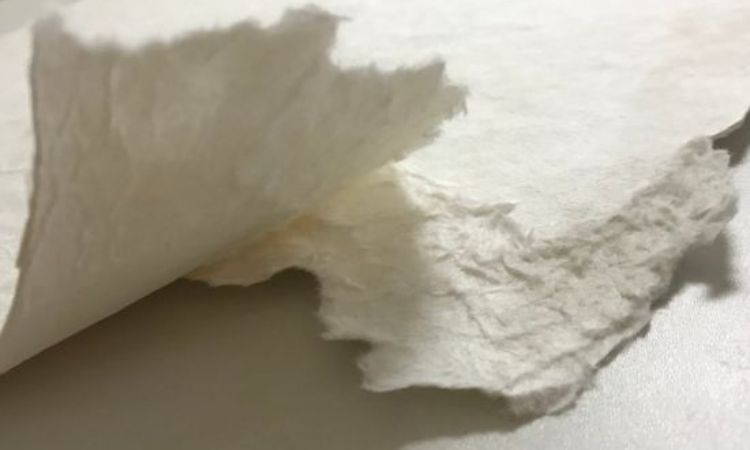

Bleached kraft pulp is a form of chemical pulp produced by the kraft process, in which wood chips are cooked in a mixture of chemicals to break down the lignin that binds the cellulose fibers together. This process results in high-strength pulp that is ideal for producing various grades of paper. The term “bleached” refers to the process of whitening the pulp to make it suitable for producing lighter, high-quality paper products.

As industries worldwide shift towards more sustainable and biodegradable materials, bleached kraft pulp has become increasingly valuable. It is particularly favored for its high tensile strength, making it a key raw material in applications where durability is essential. From packaging materials to tissue paper, the demand for bleached kraft pulp is expected to rise significantly, particularly in the coming decade.

Market Segmentation

By Process

Mechanical Process

Mechanical pulping involves grinding wood logs against a rotating stone or disk to separate fibers, making it one of the oldest and least expensive methods of pulp production. However, mechanical pulping results in lower-quality pulp compared to chemical processes and is typically used in applications that don’t require high strength or brightness. Although mechanical pulping is not as prominent in the bleached kraft pulp market, it is still used in specific applications where cost-effectiveness is key.

Chemical Process

The chemical process, particularly the kraft process, is the most common method for producing bleached kraft pulp. In this process, wood chips are cooked in a solution of sodium hydroxide and sodium sulfide, which removes lignin and frees the cellulose fibers. This results in high-strength pulp that can be easily bleached to create a lighter, more desirable product. The chemical process dominates the market because it produces higher-quality pulp, which is essential for premium paper products.

Other Processes

In addition to mechanical and chemical processes, other specialized techniques are being developed, such as the sulfite process or the soda pulping process. These methods offer specific benefits such as improved pulp brightness or better fiber recovery. However, their market share remains limited compared to the dominant chemical kraft process.

By Product

Bleached Hardwood Kraft Pulp

Hardwood trees, such as eucalyptus and birch, are typically used to produce hardwood kraft pulp. This type of pulp is characterized by shorter fibers, which are ideal for producing fine papers, tissue papers, and other high-end products. Bleached hardwood kraft pulp is particularly popular in the production of tissue papers due to its softness and absorbency.

Bleached Softwood Kraft Pulp

Softwood trees like pine and spruce produce longer fibers, which provide higher tensile strength to paper products. As such, bleached softwood kraft pulp is preferred in applications that demand durability and strength, such as packaging papers, graphic papers, and newsprint. This pulp type is essential for the production of high-performance paper grades.

By Application

Packaging Paper

The global demand for packaging paper has surged, driven by the rapid growth of e-commerce and consumer goods industries. Bleached kraft pulp is widely used in the production of corrugated boxes, flexible packaging, and retail bags. Its strength and biodegradability make it a top choice for packaging applications, which increasingly emphasize sustainability.

Tissue Paper

The tissue paper market is another key consumer of bleached kraft pulp. With rising hygiene awareness and global demand for household tissue products, bleached hardwood kraft pulp’s soft and absorbent properties are in high demand. The pulp’s eco-friendly nature further appeals to consumers and manufacturers who are moving toward more sustainable product options.

Graphic Paper

Bleached kraft pulp plays a significant role in the production of graphic paper, including high-quality printing papers, book papers, and brochures. This pulp’s superior brightness and smooth texture make it ideal for applications where print clarity and image quality are essential.

Newsprint Paper

While the demand for newsprint paper has declined with the digital age, it still remains a key segment in certain regions. Bleached kraft pulp continues to be used in the production of newsprint, where the pulp’s cost-effectiveness and quality are valuable.

Specialty Paper

Specialty papers, such as those used in labels, filters, and medical products, require high-strength, durable pulp. Bleached kraft pulp meets these needs and is used in the manufacture of specialty papers with distinct functional properties.

Other Applications

Beyond the primary applications mentioned above, bleached kraft pulp is used in various niche applications, including the production of wallpapers, art papers, and even biodegradable wipes.

Regional Analysis

The demand for bleached kraft pulp varies significantly across regions, driven by industrial and consumer demand for paper products.

- North America: The North American market is driven by the high demand for packaging and tissue paper. Strong sustainability initiatives across the region further fuel the adoption of bleached kraft pulp.

- Europe: Europe is one of the largest markets for bleached kraft pulp, with major producers located in Sweden, Finland, and Germany. The region’s growing focus on recycling and sustainable production methods contributes to steady growth in the market.

- Asia-Pacific: The Asia-Pacific region, particularly China and India, is witnessing a rapid increase in industrialization, which is boosting the demand for bleached kraft pulp. The rise in e-commerce and consumer goods manufacturing in these countries plays a significant role in the market’s growth.

- Latin America: Countries like Brazil are becoming increasingly important suppliers of raw materials for bleached kraft pulp, contributing to market growth in Latin America.

- Middle East & Africa: The market in the Middle East and Africa is growing, particularly in countries where paper production is a significant industry. However, challenges related to raw material sourcing and energy costs remain.

Market Dynamics

Drivers of Market Growth

- Sustainability: As more industries shift toward eco-friendly alternatives, bleached kraft pulp benefits from its biodegradable nature and suitability for recycling.

- E-commerce Growth: The booming e-commerce sector requires more sustainable packaging solutions, driving demand for bleached kraft pulp in packaging applications.

- Technological Advancements: Ongoing improvements in pulp production technologies are making the process more efficient, which is reducing costs and increasing the quality of the end product.

Challenges

- Raw Material Sourcing: The cost and availability of high-quality wood, particularly hardwood and softwood, pose challenges for pulp producers.

- Environmental Regulations: Stringent environmental policies may increase operational costs for pulp manufacturers and affect market dynamics.

Opportunities

- Emerging Markets: Increased industrialization in emerging economies offers significant growth opportunities for bleached kraft pulp.

- Innovative Applications: Research into new uses for bleached kraft pulp, including in biodegradable packaging materials, opens up new markets for manufacturers.

Competitive Landscape

The bleached kraft pulp market is competitive, with key players like International Paper, UPM-Kymmene Corporation, and Stora Enso leading the way. These companies are focusing on sustainable practices, technological advancements, and strategic acquisitions to strengthen their market position.

Future Outlook

The global bleached kraft pulp market is expected to grow steadily at a CAGR of 5% from 2025 to 2034. The ongoing demand for sustainable paper products, coupled with advancements in pulp production technology, will likely shape the future of this market.