APMT insert is designed for CNC machines, delivering high-performance milling, smooth cuts, and long tool life for precise, efficient machining.

High-Performance APMT Inserts for Smooth & Precise CNC Milling

CNC milling has become the backbone of modern manufacturing, enabling high precision and efficient production in industries from aerospace to automotive. At the heart of this precision lies the cutting tools—particularly milling inserts such as the apmt 1135, apmt 1604, and apmt 16. Today’s manufacturers demand tooling solutions that deliver smooth surface finishes, extended tool life, and consistent performance. High-performance APMT inserts are designed to meet these needs precisely, making them essential components of any CNC milling setup.

Understanding APMT Inserts and Their Role in Milling

APMT inserts are square, indexable milling inserts commonly used for shoulder milling, face milling, and slotting. The designation “APMT” refers to a specific geometry and tolerance class that provides multi-directional cutting edges. These items are ideal for medium- to finishing-level operations and are highly valued for their balance of durability and precision. Whether it is a standard ampt 16 insert or the specialised apmt 1135 insert, these components play a pivotal role in achieving smooth machining results.

Why High-Performance Inserts Matter in CNC Milling

Precision is everything in CNC milling. A slight deviation can lead to poor surface finish, rejects, and increased production costs. High-performance APMT inserts are engineered to handle complex materials and tight tolerances. These inserts feature advanced coatings and edge preparations that reduce cutting forces, improve chip evacuation, and ensure consistent performance—even at high speeds. The result? Reduced cycle times and superior part quality.

Key Features of Advanced APMT Milling Inserts

Modern APMT inserts boast several technological advancements:

- Enhanced substrate composition for wear resistance

- Multi-layered coatings to protect against heat and abrasion

- Precisely ground cutting edges for improved surface finish

- Uniform chip breakers for efficient material removal

These features are available across different variants, including apmt 1604 inserts and apmt 1135 insert models, ensuring the right solution for specific milling needs.

Choosing the Right Insert for Your Application

Selecting the correct insert depends on:

- Material being machined

- Desired surface finish

- Cutting speed and feed requirements

- Machine capability

For tough alloys and high precision components, high-performance inserts with advanced coatings and optimised geometry can make a significant difference. The apmt 16 insert family, for example, offers versatile solutions for general-purpose to semi-finish milling.

The Versatility of APMT Inserts in Different Milling Operations

APMT inserts are flexible and can be used in:

- Profile milling

- Face milling

- Plunge milling

- Heavy rough milling (with appropriate grades)

This versatility simplifies inventory management and ensures machinists can use the same tooling platform across a variety of operations, which is especially useful when combined with tools such as a 25mm apmt inserted cutter.

Material Compatibility: From Aluminum to Hardened Steel

Different workpiece materials require different tooling approaches. High-performance APMT inserts are available in various grades designed for:

- Aluminum and non-ferrous materials

- Stainless steel

- Hardened steel

- Cast iron

Selecting the right grade and edge preparation ensures optimised cutting conditions, fewer tool changes, and improved productivity. For example, specialised apmt 1604 inserts are often chosen for tougher materials due to their enhanced coating and substrate properties.

Surface Finish and Tolerance: Achieving Precision with APMT

Surface finish is a crucial quality metric in CNC milling. APMT excels at delivering tight tolerances and smooth finishes due to its precisely engineered geometry and edge sharpness. Whether it’s a fine finish or a semi-finish, APMT inserts, such as the apmt 1135 insert, deliver reliable performance that meets industrial standards.

The Importance of Coatings in High-Performance Milling

Coatings play a significant role in enhancing the performance of milling inserts. Advanced PVD and CVD coatings reduce friction and heat build-up, enabling higher cutting speeds and longer tool life. Coatings such as TiCN, AlTiN, and multilayer composites enhance durability, making inserts like the apmt 16 insert ideal for both general and demanding applications.

Impact of Tool Geometry on Chip Control and Heat Management

Chip control affects both surface finish and machine performance. Poor chip evacuation can lead to tool breakage and compromised part quality. High-performance APMT inserts feature optimised chip breaker designs that efficiently manage chips during cutting. Tools such as the 25mm apmt inserted cutter are engineered to pair perfectly with these inserts, improving material flow and reducing heat concentration.

Maximising Tool Life with Proper Machining Practices

Selecting high-quality inserts is only part of the solution. To maximise tool life:

- Use correct feeds and speeds

- Ensure rigid workholding

- Maintain proper coolant application

- Minimize vibration

Combined with premium inserts such as apmt 1604, good machining practices help reduce downtime and lower operating costs.

Reducing Production Downtime and Costs

Downtime costs money. High-performance milling inserts help reduce machine stops by offering longer tool life and predictable wear patterns. Quick indexable inserts mean fewer changeovers and greater uptime. When paired with robust tools such as a 25mm apmt inserted cutter, these inserts contribute to smoother and uninterrupted production cycles.

Custom Solutions for Specialised Milling Requirements

No two machining jobs are identical. Some applications require specialised grades or geometries to achieve optimal results. Manufacturers today offer customised APMT solutions tailored to specific materials and cutting conditions. Whether it’s a unique grade for aerospace alloys or a modified chip breaker for deeper cuts, these solutions expand the possibilities of CNC milling.

Real-World Performance: Case Studies and Industrial Examples

In industrial environments, companies using high-performance APMT inserts have reported:

- Improved surface finishes

- Increased part consistency

- Reduced insert inventory

- Lower overall tooling costs

Integrating inserts such as apmt 1135 into everyday milling has delivered performance gains and measurable ROI—especially when paired with properly matched cutters.

The Future of Milling: Innovation in Insert Technology

Tooling manufacturers continue to develop inserts with better wear resistance, innovative coatings, and improved geometries. Smart tooling equipped with sensors and data analytics is also emerging, offering real-time insights into tool wear and performance. As CNC machines become more advanced, high-performance inserts such as the apmt 16 insert family will evolve to meet the increasing demands of automation and precision.

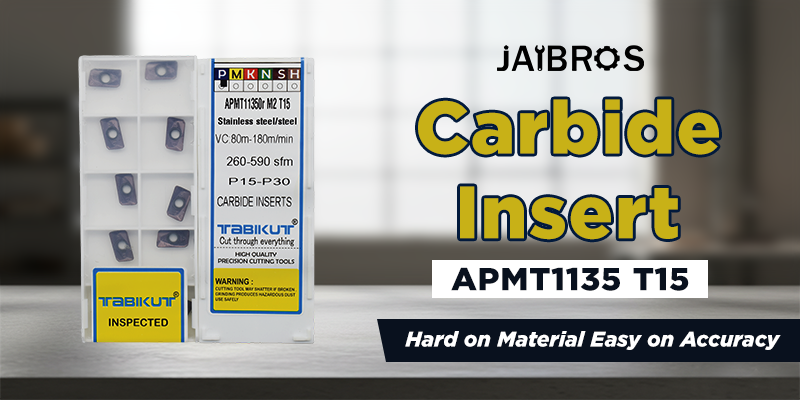

Jaibros: Delivering Precision Tooling Solutions

Jaibros is a trusted provider of high-quality CNC milling tools and tooling solutions. With a focus on performance and reliability, Jaibros offers an extensive range of APMT inserts—including apmt 1135 insert, apmt 1604 inserts, apmt 16 insert, and compatible tooling like the 25mm apmt inserted cutter—designed to meet diverse machining needs in automotive, aerospace, die and mould, and general manufacturing sectors.

At Jaibros, quality assurance and customer satisfaction are core principles. Our products undergo stringent testing to ensure optimal performance and longevity. We are committed to helping manufacturers enhance productivity, reduce costs, and achieve superior machining results. With Jaibros, you get the latest in tooling innovation backed by expert support and service.

Conclusion

High-performance APMT inserts are integral to achieving smooth, precise, and efficient CNC milling operations. With advanced designs, coatings, and adaptable applications, these inserts—such as apmt 1135 insert, apmt 1604 inserts, apmt 16 insert, and paired tools like 25mm apmt inserted cutter—provide a reliable foundation for quality machining. By selecting the correct insert and partnering with a reputable provider like Jaibros, manufacturers can achieve better surface finishes, longer tool life, reduced downtime, and greater overall productivity.