Discover why CCMT inserts with a CCMT boring bar deliver superior accuracy, smooth finishing, and reliable performance for precision boring applications.

Why CCMT Inserts Deliver Superior Precision in Boring Operations

Precision boring is one of the most demanding tasks in machining, requiring accuracy, stability, and dependable tooling. Among the many inserts used for boring operations, CCMT boring bar setups have become a popular choice for machinists who prioritize surface finish, accuracy, and tool life. Whether you’re performing fine boring or handling tough materials, CCMT inserts deliver consistency that professionals rely on.

In this blog, we will explore why CCMT inserts are ideal for precision boring applications, how they improve machining quality, and how the right CCMT boring bar setup can elevate productivity. We’ll also touch on ccmt boring bar angle, 12mm ccmt boring bar, and the CCMT boring bar set options used in various industries.

Understanding CCMT Inserts in Boring Operations

CCMT inserts are typically positive-rake carbide inserts known for their smooth cutting performance. When paired with a compatible CCMT boring, these inserts offer increased stability and lower cutting forces, making them ideal for boring internal diameters with high accuracy.

Their cutting-edge design allows for reduced chatter, better chip flow, and fine surface finishing—factors that play a huge role in applications requiring micrometer-level precision.

Why CCMT Inserts Are Ideal for Precision Boring

1. Superior Cutting Stability

One of the main reasons machinists prefer a boring bar setup is the stable cutting action. The insert geometry minimizes vibration, which is critical during deep boring operations. Even at higher speeds, the insert delivers a smooth cutting motion, preventing tool deflection.

The optimized ccmt boring bar angle contributes significantly to maintaining this stability by offering the right approach angle to enhance chip evacuation and reduce friction.

2. Excellent Surface Finish

Precision boring often demands a mirror-like finish. CCMT inserts provide smooth chip control and fine cutting performance, ensuring the material is removed cleanly without rough edges.

When combined with a properly sized boring bar—such as a 12mm ccmt boring bar—the insert ensures the correct balance of strength and precision, producing high-quality internal surfaces.

3. Versatility Across Materials

Another advantage of CCMT inserts is their versatility. They can handle a wide range of materials, including:

- Mild steel

- Stainless steel

- Cast iron

- Aluminum

- Bronze

This makes the boring bar setup suitable for job shops, manufacturing units, and precision engineering companies working with different material grades.

4. Long Tool Life and Cost Efficiency

Carbide CCMT inserts are known for their durability. Their heat resistance and wear resistance result in a longer tool life, reducing tooling costs and downtime. Since most boring bar set options include multiple compatible inserts, it becomes easier for machinists to switch between operations without needing entirely new tooling.

5. Ideal for Both Roughing and Finishing

Although CCMT inserts excel in finishing, they also work effectively for light-roughing operations. This dual-benefit capability helps shops streamline operations, as a boring bar can often handle a complete boring cycle from start to finish.

Factors to Consider When Using CCMT Inserts for Boring

1. Correct Boring Bar Size

Choosing the right bar size, such as a 12mm ccmt boring bar, ensures rigidity and reduces the chance of tool vibration.

2. Proper Insert Geometry

The cutting edge radius also plays a role in determining the accuracy of the cut and surface finish.

3. Ideal Cutting Speed and Feed

Although CCMT inserts support high-speed machining, the exact cutting parameters depend on the material and machining setup.

4. Correct Boring Bar Angle

The ccmt boring bar angle affects tool entry and chip removal. Using the correct angle results in better tool performance and longer insert life.

Benefits of Using a CCMT Boring Bar Set

A boring bar set usually includes multiple boring bars with various lengths and diameters, along with compatible CCMT inserts. This setup ensures flexibility, allowing machinists to handle different types of internal turning and boring tasks. It also reduces the need to purchase individual bars for every job, making it a cost-efficient investment for small and large workshops.

Conclusion:

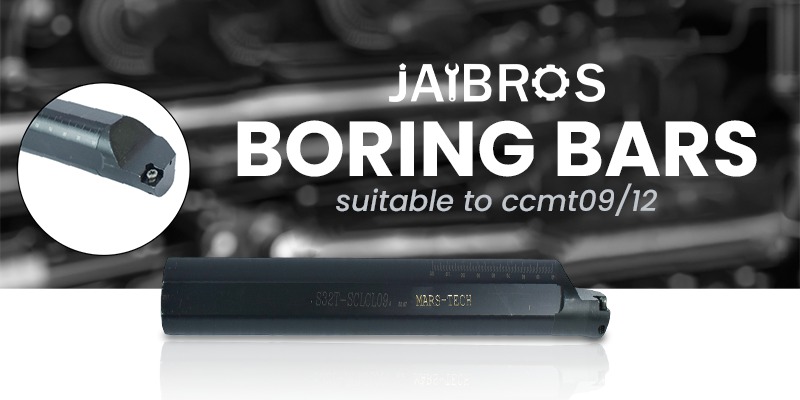

In precision machining, accuracy and reliability are non-negotiable. CCMT inserts paired with a quality boring bar deliver outstanding stability, long tool life, and excellent surface finish. Whether you’re working with a 12 mm CCMT boring bar, adjusting your ccmt boring bar angle, or using a complete CCMT boring bar set, the benefits remain consistent across applications. Jaibros provides a reliable range of machining tools, including boring bars, cutting inserts, and precision accessories. Known for quality and performance, Jaibros supports machinists with tools that enhance accuracy, productivity, and long-term durability.

FAQs

- What makes CCMT inserts suitable for precision boring?

Their positive rake geometry ensures smooth cutting, less vibration, and a fine surface finish.

- Can CCMT inserts be used for deep boring?

Yes, when paired with a stable CCMT boring bar, they offer excellent performance for deep boring operations.

- What is the importance of the ccmt boring bar angle?

The angle affects chip flow, cutting pressure, and overall accuracy of the boring process.

- Is a 12mm ccmt boring bar good for small machines?

Yes, it is compact, rigid, and ideal for precision work on smaller CNC and manual machines.

- Are CCMT boring bar sets worth buying?

Absolutely—they offer multiple bar sizes and inserts, making them cost-effective and versatile for different boring tasks.