In today’s world, sustainability has become a top priority for businesses across industries. With increasing regulatory pressures and growing environmental concerns, companies are expected to adopt practices that minimize their ecological footprint. One such solution is the Zero Discharge System (ZDS), designed to ensure that no liquid waste leaves the facility untreated or unprocessed. Choosing the right system can make a significant difference in compliance, operational efficiency, and long-term cost savings. This guide explains how zero discharge systems work, their types, and the factors businesses should consider when selecting the best one.

Understanding Zero Discharge Systems

A Zero Discharge System is an advanced wastewater treatment approach that ensures every drop of water used in industrial processes is either purified, reused, or evaporated, leaving behind no liquid effluent. Unlike conventional wastewater treatment methods that discharge treated water into rivers or municipal lines, ZDS ensures total recycling and reuse within the facility.

This technology is particularly important in industries such as textiles, pharmaceuticals, chemicals, food processing, and power generation, where wastewater contains high levels of dissolved solids, heavy metals, and other contaminants. By adopting ZDS, businesses not only comply with environmental laws but also strengthen their sustainability initiatives.

What is a Zero Discharge System?

A Zero Discharge System (ZDS) is a combination of advanced filtration, evaporation, and recovery technologies that aim to recycle wastewater completely. The primary goal is to achieve Zero Liquid Discharge (ZLD), meaning that no liquid effluent exits the facility. Instead, water is purified and reused, while salts and other byproducts are collected in solid form for safe disposal or reuse.

In simple terms, a ZDS allows industries to:

Reuse up to 95–100% of wastewater.

Minimize dependency on fresh water.

Ensure compliance with pollution control regulations.

Reduce environmental risks associated with wastewater discharge.

Key Components of Zero Discharge Systems

While system designs may vary depending on the industry, most zero discharge systems include the following components:

Pre-treatment Units – Screens, clarifiers, and chemical dosing systems to remove suspended solids and neutralize pH.

Membrane Filtration Units – Reverse osmosis (RO) or ultrafiltration (UF) systems that separate dissolved solids from water.

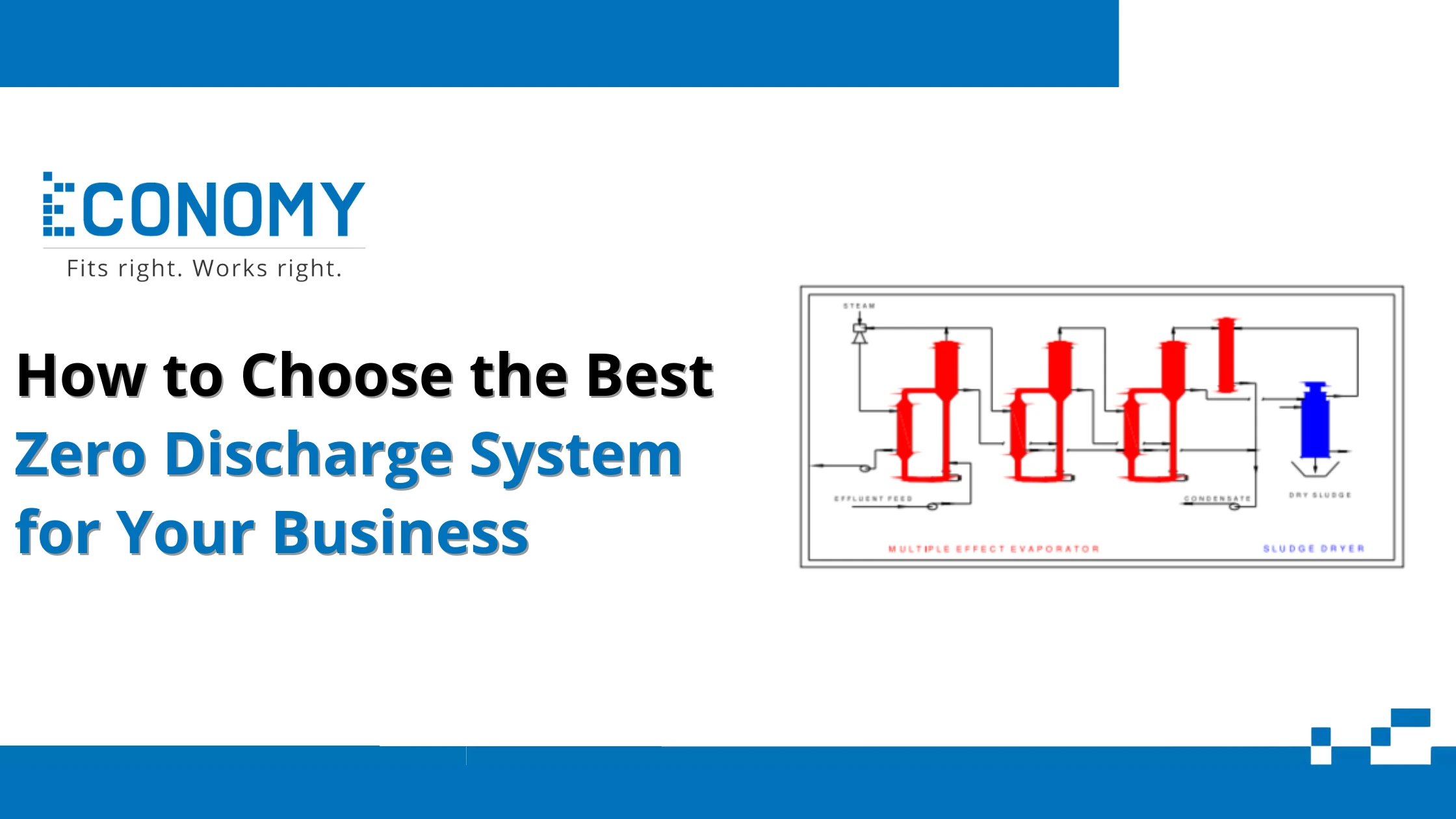

Evaporation Units – Multi-effect evaporators (MEE) or mechanical vapor recompression (MVR) systems that concentrate wastewater by evaporating water.

Crystallizers – Used to convert concentrated brine into solid salt, ensuring zero liquid output.

Sludge Handling Units – Dryers, centrifuges, or filter presses that process sludge into disposable or reusable solids.

Each component plays a crucial role in ensuring that wastewater is treated thoroughly and safely.

How Zero Discharge Systems Work

The process of achieving zero discharge typically involves multiple stages:

Wastewater Collection – All wastewater streams from different processes are collected.

Pre-treatment – Removal of large particles, oil, and grease to protect downstream equipment.

Membrane Filtration – Water passes through ultrafiltration or reverse osmosis systems to separate dissolved salts and impurities.

Concentration and Evaporation – Remaining brine is concentrated in evaporators until water vapor separates from contaminants.

Crystallization – The final concentrated brine is converted into crystals (solid salts), leaving behind reusable water.

Reuse – Purified water is recycled back into the process, achieving zero liquid waste discharge.

By combining advanced separation and evaporation techniques, ZDS ensures nearly complete recovery of water.

Types of Zero Discharge Systems

Depending on design and application, classified into several Types of Zero Discharge Systems:

Membrane-Based Systems – Use reverse osmosis and nanofiltration to treat wastewater with moderate salt content. Ideal for industries with relatively clean wastewater streams.

Thermal-Based Systems – Rely on evaporators and crystallizers, suitable for highly saline or complex wastewater streams.

Hybrid Systems – Combine membrane and thermal technologies for maximum efficiency and cost-effectiveness.

Modular Systems – Compact, pre-engineered systems designed for small-scale industries or pilot plants.

The choice of system depends on wastewater characteristics, industry requirements, and cost considerations.

Factors to Consider When Choosing a Zero Discharge System

Selecting the right zero discharge system requires a detailed evaluation of multiple factors:

Nature of Wastewater – Analyze chemical composition, salinity, and contaminants to determine suitable technology.

Industry Requirements – Different industries (textile, pharma, power, etc.) require tailored solutions.

Operational Costs – Evaluate energy consumption, chemical usage, and maintenance costs.

System Scalability – Ensure the system can expand with production growth.

Automation and Monitoring – Choose systems with advanced controls for efficiency and reduced manual intervention.

Compliance Standards – Verify that the system meets local environmental regulations and industry standards.

Vendor Expertise – Select experienced providers who offer end-to-end support, from design and installation to training and maintenance.

A careful analysis of these factors ensures a system that is not only compliant but also cost-efficient in the long run.

Benefits of Choosing the Right Zero Discharge System

The advantages of implementing the right ZDS go beyond regulatory compliance:

Water Conservation – Reuse of treated water reduces freshwater consumption.

Cost Savings – Reduces water procurement and wastewater disposal costs.

Environmental Responsibility – Eliminates pollution and improves corporate sustainability image.

Operational Reliability – Consistent water quality improves process efficiency and product quality.

Regulatory Compliance – Ensures smooth operations without legal or environmental penalties.

By aligning environmental goals with business operations, ZDS provides both ecological and financial benefits.

Common Mistakes to Avoid

While adopting zero discharge systems, businesses often make avoidable mistakes, such as:

Underestimating Wastewater Complexity – Ignoring detailed water analysis can lead to system failures.

Choosing Based on Cost Alone – Low-cost systems may not provide long-term efficiency or reliability.

Neglecting Maintenance Needs – ZDS requires regular monitoring and upkeep to remain effective.

Overlooking Scalability – Choosing a system that cannot adapt to future production increases.

Ignoring Vendor Expertise – Selecting inexperienced providers can result in poor system design and frequent breakdowns.

Avoiding these pitfalls ensures smooth adoption and long-term success.

Conclusion

A Zero Discharge System is no longer just an option—it is becoming a necessity for industries striving for sustainability and compliance. By understanding what a ZDS is, how it works, and the various types available, businesses can make informed decisions tailored to their specific wastewater challenges.

When selecting a system, companies should prioritize wastewater characteristics, operational costs, scalability, and vendor expertise. The right system not only ensures zero liquid discharge but also delivers cost savings, water conservation, and improved operational efficiency.

In the long run, investing in the best zero discharge system is not just about meeting regulations—it is about building a sustainable future for the business and the environment.